The first affordable, mass marketed, “no gas, no tailpipe,” zero-emission era vehicle is entering into its third year of production. The LEAF® is now being assembled in Smyrna, Tennessee, including battery production.

Mechanical

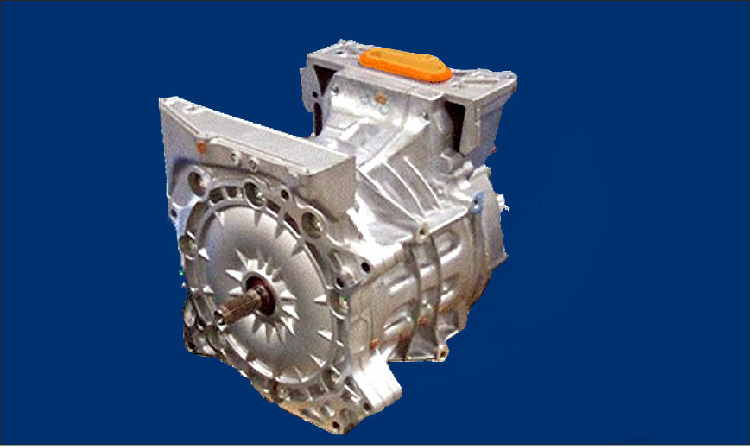

80kW AC Synchronous Motor

For 2013, the LEAF® is again powered by an advanced lithium-ion battery composed of 48 compact modules and a high-response 80kW AC synchronous motor that generates 254Nm, and @107 horsepower and 187 lb-ft of torque. The traction motor contains an “Interior Permanent Magnet Synchronous Motor (IPMSM)”. A permanent magnet is embedded inside the rotor core, and the rotating magnetic field generated by the stator coil is used to generate rotational torque.

The traction motor is able to generate torque even when the vehicle is stopped, and outputs maximum drive torque when the vehicle starts moving in order to provide good initial acceleration.

6.6 kW On-Board Charger (6.0kW Output) (SV & SL)

Changes to this years LEAF® start with improved energy efficiency due to refined aerodynamics, a wider range of regenerative braking, and improved energy management. For 2013, the LEAF® SV and SL grades feature a new 6.6 kW onboard charger that reduces 220V charging time nearly in half. The stronger charger will allow the LEAF® to recharge in half the time taken by current models, which need about 7 hours to recharge with a 220-volt power supply. This system is also optionally available with the new lower trim S grade LEAF® added this year, which in standard form will utilize a 3.6 kW on-board charger. All the 2013 LEAF® models come with a standard portable trickle charge cable (120V EVSE).

Chassis

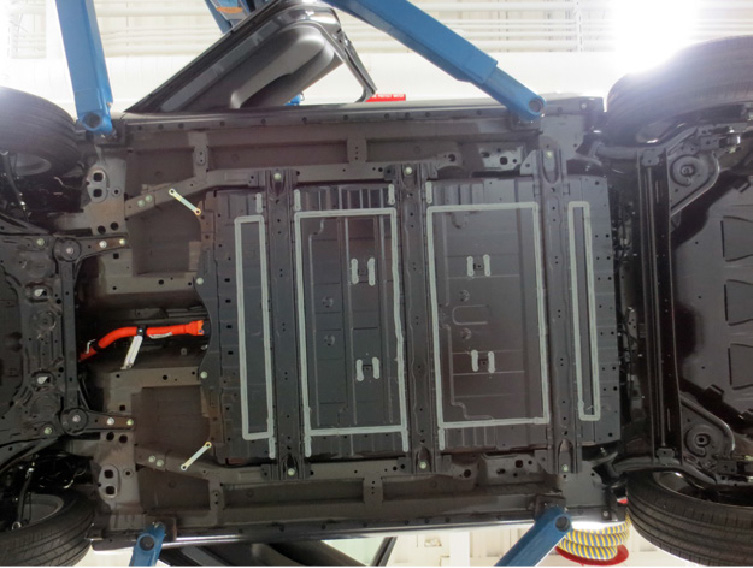

All-new Dedicated EV Platform

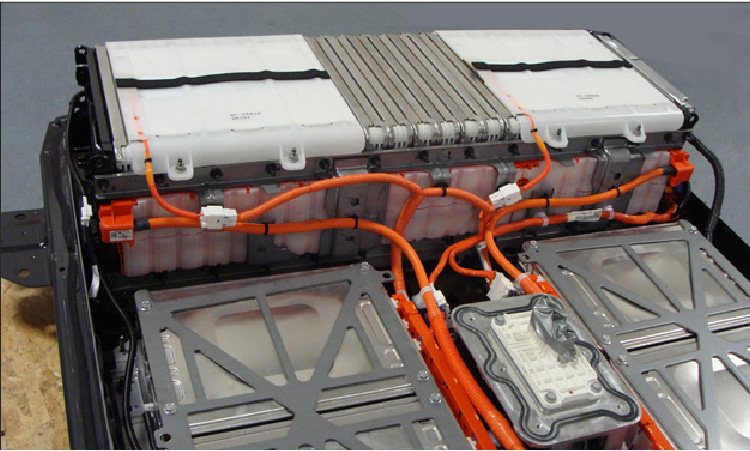

The front-wheel drive LEAF® again uses a dedicated EV platform with its batteries housed in the floor for optimum vehicle packaging and weight distribution. This allows a high degree of packaging flexibility. The body design includes a rigid-mounted battery frame, which helps provide greater body rigidity compared to a conventional compact car.

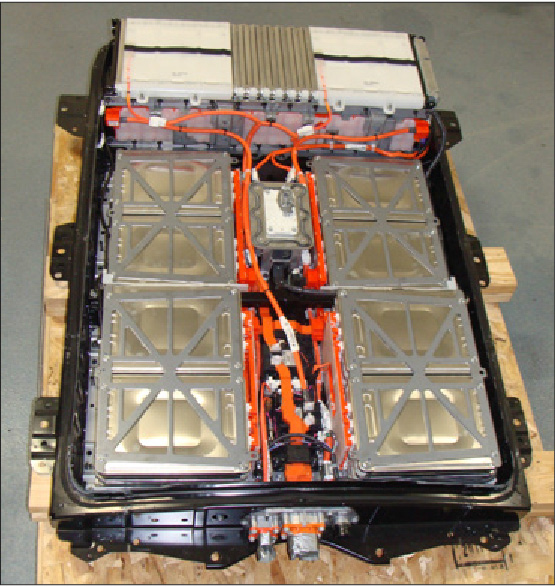

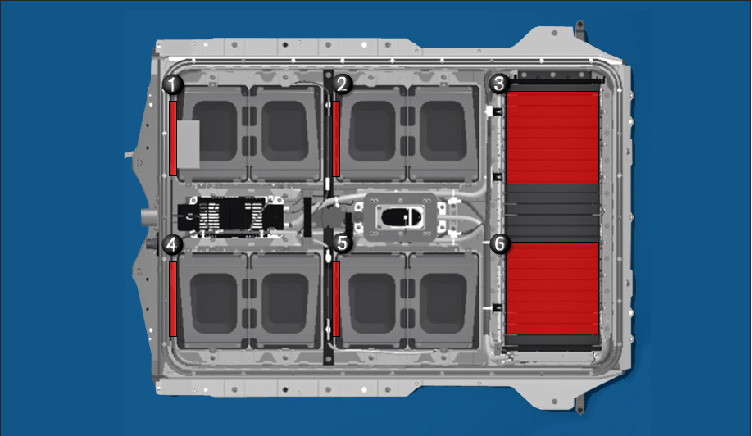

LEAF’s 24 kWh Lithium Ion (Li-Ion) Battery

The LEAF’s AESC Li-Ion Battery is comprised of 48 compact modules of four cells each (192 cells total). The new Smyrna battery was developed by the Automotive Energy Supply Corporation (AESC), a joint venture of Nissan and NEC. These new batteries are designed to maximize drive time and minimize charging time. Unlike conventional cylindrical batteries, the thin, compact laminated cells offer more flexibility in design applications.

The advanced lithium-ion battery pack carries an industrycompetitive warranty of 8 years or 100,000 miles. In addition, under an expanded New Electric Vehicle Limited Warranty, Nissan will protect against capacity loss in LEAF® batteries that fall below nine bars, of the available 12 bars displayed on the vehicle’s battery capacity gauge, for the first five years or 60,000 miles in the United States, whichever comes first.

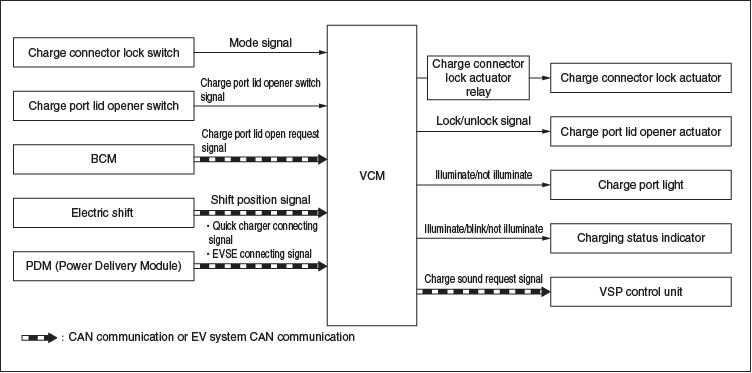

Quick Charge Port

The Nissan LEAF® offers a number of charging options. A charge port is located in the front body for the 220V charger and portable trickle charge cable (110V). A charge port light and lock has been added for 2013.

When the quick charge connector is connected to the quick charge port and the start switch of quick charger is pressed, the PDM (Power Delivery Module) transmits an EV system activation request signal to VCM (Vehicle Control Module). The VCM then activates the F/S CHG relay.

chargeable power signal received from the Li-ion battery controller and the chargeable power signal received from the PDM. The VCM then sends the maximum charge power signal to the PDM. The PDM converts the Maximum charge power signal to a charge current request signal and transmits it to the quick charger.

Simultaneously, the PDM activates the quick charge relay, and the VCM activates system main relay 1 and system main relay 2, thus starting the quick charge.

Suspension

The 2013 Nissan LEAF® again uses an independent strut suspension with stabilizer bar in front and a torsion beam rear axle with integrated stabilizer bar. Responsive steering is provided by a vehicle-speed-sensitive electric power steering system.

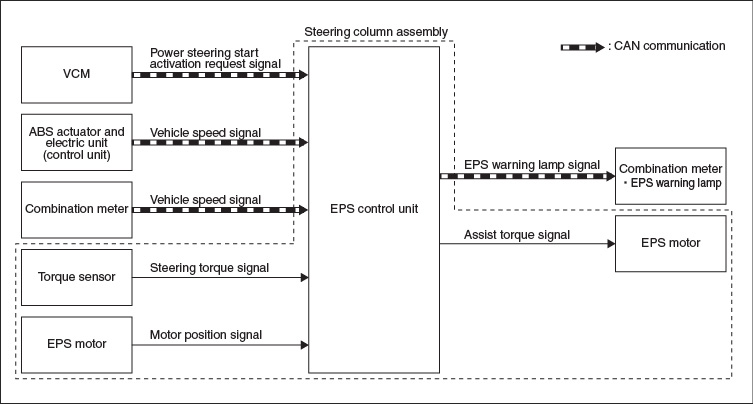

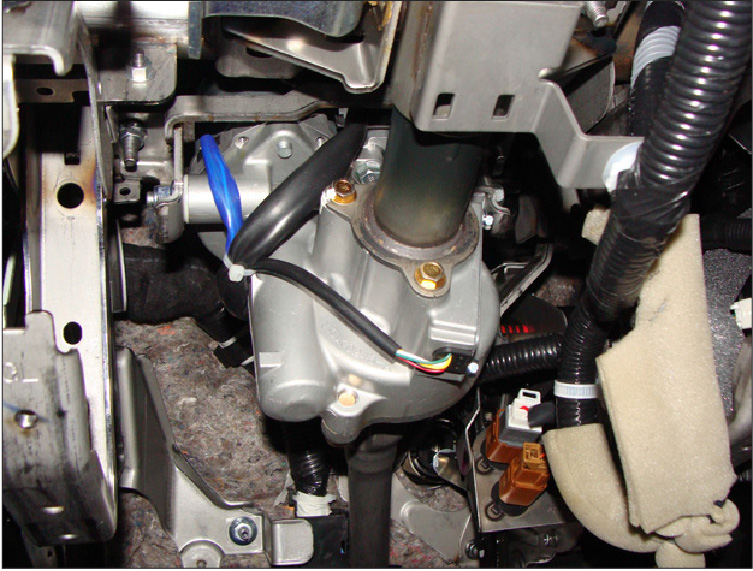

Steering

The 2013 LEAF® is equipped with vehicle speed-sensitive electric power steering

The EPS (Electronically Controlled Power Steering) unit performs an arithmetical operation on data, such as steering wheel turning force (sensor signal) from the torque sensor, vehicle speed signal, etc. This allows it to generate the optimum assist torque signal to the EPS motor according to the driving condition.

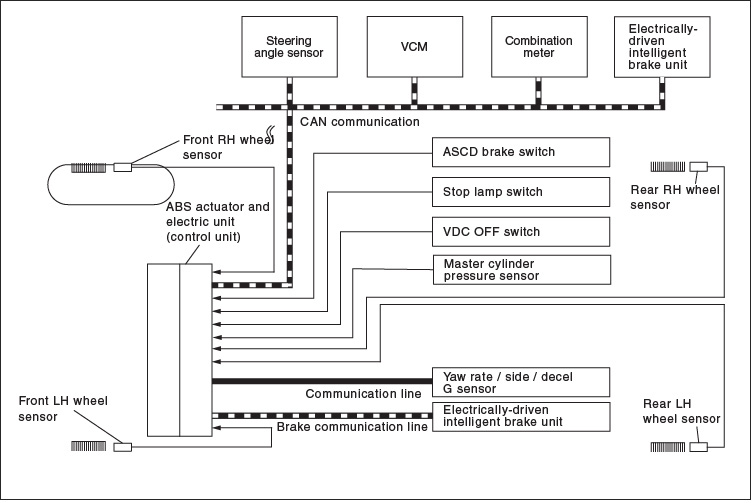

Brake System

The LEAF® is equipped with a hydraulic braking system and a regenerative brake system. The hydraulic brake system is similar to the brakes used on conventional vehicles and provides the majority of the braking. The regenerative brake system also provides engine braking and recaptures energy acting as an electric generator. This recapture of energy when the brakes are applied produces electricity that feeds the Liion battery and operates based on battery condition.

Electronic Brake force Distribution (EBD) and Brake Assist (BA)

Braking is provided by power-assisted front vented disc/solid rear disc brakes with Antilock Braking System (ABS), Electronic Brake force Distribution (EBD) and brake assist. The brake control system switches fluid pressure of each brake caliper to increase, to hold, or to decrease pressure, according to signals from the control unit in the ABS actuator and electric unit (control unit). This control system is applied to VDC function, TCS function, ABS function, EBD function, Brake Limited Slip Differential (BLSD) function and brake assist function.

The control unit built in the ABS actuator and Electrically-driven Intelligent Brake Unit controls fluid pressure of the brake calipers, respectively, by operating each valve.

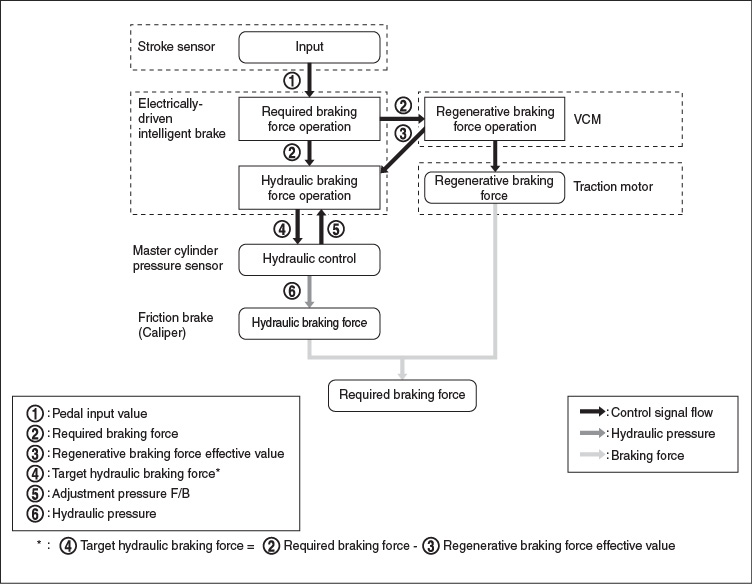

Cooperative Regenerative Brake Function

The primary purpose of the regenerative brake function is to generate a charge to the Li-ion battery. A secondary benefit is “engine braking”.

During deceleration, the traction motor inverter drives the traction motor to function as a generator based on the regenerative torque command signal sent via EV system CAN from the VCM (Vehicle Control Module), converting the kinetic energy generated by rotation of the tires into electrical energy. The converted electrical energy charges the Li-ion battery.

The regenerative torque that is generated can be used as braking force, acting similar to engine braking and reducing the burden on the service brakes.

A regenerative brake drives the traction motor to act as an alternator, and converts the kinetic energy produced by rotation of the tires into electrical energy. The converted electrical energy charges the Li-ion battery.

- When the brakes are operated (during driving), the electrically-driven intelligent brake unit calculates the required braking force based on the input value from the stroke sensor (indicating the amount of brake pedal operation) It sends the result to the VCM.

- The VCM calculates the regenerative braking force needed to pro duce the required braking force, and sends the result to the electrically-driven intelligent brake unit. At the same time, the traction motor inverter uses the traction motor to perform regenerative braking.

- The electrically-driven intelligent brake unit calculates the hydraulic braking force again based on the regenerative braking force result from the VCM and the calculated result for hydraulic braking force. Based on the calculated result for hydraulic braking force, the electrically-driven intelligent brake unit uses the motor inside the electrically-driven intelligent brake unit to move the master cylinder piston, adjusting the fluid pressure inside the master cylinder so that the fluid pressure that is actually applied matches the target fluid pressure.

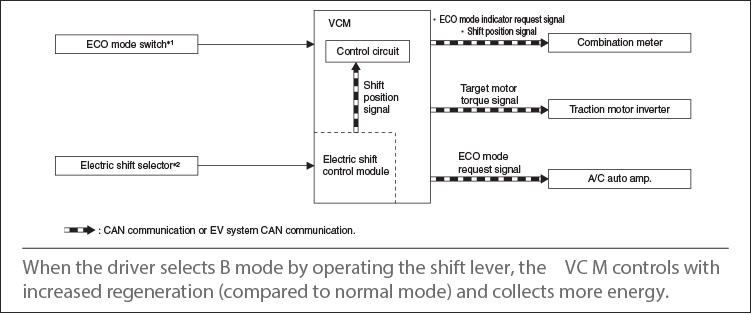

Three Drive Modes

The 2013 LEAF® has three drive modes: Normal, ECO-Mode, and B-mode (SV & SL). The ECO mode increases regenerative braking, assists in limiting motor output and reduces HVAC power output. When the driver selects ECO mode by operating the shift lever (S trim level without steering switch models) or the ECO mode switch (SV/SL trim level with steering switch models), VCM controls to a gentle acceleration (compared to normal mode) and reduces electricity consumption by reducing energy usage during acceleration and deceleration. In addition, VCM transmits an ECO mode request signal to the A/C auto amp. and reduces the electricity consumption of A/C compressor by turning down the air conditioner.

The new VCM transmits an ECO mode indication request signal to the combination meter via CAN communication to turn ON the ECO mode indicator lamp.

In the newly available B-mode, regenerative braking is increased. The electric motor creates more energy. This new B-mode (SV and SL grades only) allows the driver to engage an even more aggressive level of regenerative braking while decelerating, such as going down hills. The “B-mode” is in addition to the normal and ECO drive modes.

![]()

Do not operate the shift lever while the accelerator pedal is depressed, except when shifting to the ECO position.

The following operations are not allowed because excessive force would be applied to the traction motor which would result in damage to the vehicle:

- Moving the shift lever to the R (Reverse) position when driving forward.

- Moving the shift lever to the D (Drive) or ECO position when reversing.

If these operations are attempted a chime will sound and the vehicle shifts to N (Neutral) position.

Hill Start Assist

The 2013 LEAF® is equipped with Hill Start Assist. This function maintains brake fluid pressure so that the vehicle does not move backwards in the time it takes for the driver to release the brake pedal to depress accelerator pedal to start the vehicle while it is stopped on an uphill slope.

- This function operates when the vehicle is stopped on a uphill slope of 10% grade or more and the selector lever is in the position other than P or N.

- Hill Start Assist function is only a start aid. It maintains the brake fluid pressure for approx. 2 seconds after releasing the brake pedal, and then decreases the pressure gradually. If the vehicle can start by the accelerator operation, the brake is released automatically and a smooth start can be performed. After 2 seconds the vehicle will begin to roll back and Hill Start Assist will stop operating completely.

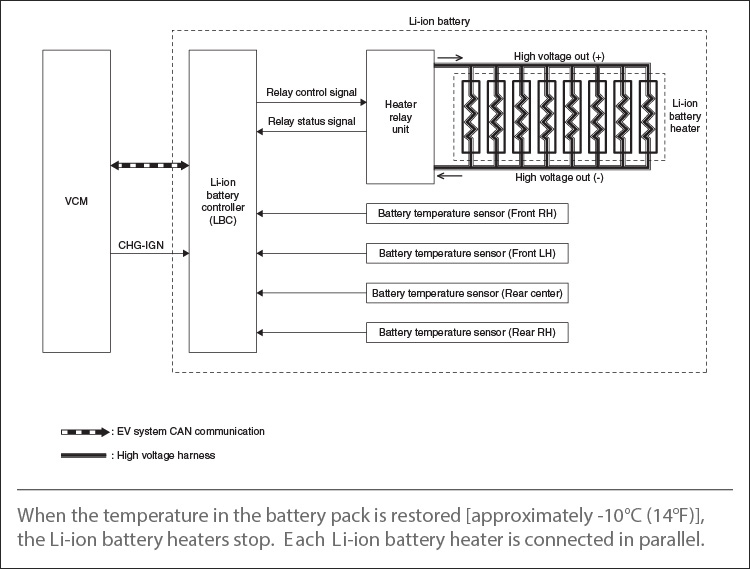

Li-ion Battery Heaters

There are six PTC heater elements in the battery system.

When the Li-ion batteries’ inside temperature drops down to -20°C/-4°F, the Li-ion battery heater control system automatically activates the Li-ion battery heaters. This helps protect the Li-ion battery from freezing during extreme cold weather and helps prevent the decline in battery output. The Li-ion battery controller (LBC) detects a temperature in the battery pack, according to a signal transmitted from the battery temperature sensor installed to the battery pack and judges the need for activation of the Li-ion battery heaters. When the relay built in the heater relay unit turns ON, high voltage power is supplied to each Li-ion battery heater.

Once the Li-ion battery temperature is restored to approximately -10°C/14°F, the Li-ion battery heater control system turns OFF the Li-ion battery heaters.

Note:

The Li-ion battery heaters are connected in parallel.

Even when the power switch is OFF, the LBC periodically activates the heaters to help protect the Li-ion battery from freezing.

Four front Li-ion battery heaters are installed to each front module stack.

Two rear Li-ion battery heaters are installed to the rear module stack.

Exterior

LEAF® rides on a 106.3-inch wheelbase, with a 175.0-inch overall length, 69.7-inch width and 61.0-inch height. Dimensionally, the LEAF® falls in between the Altima and Versa size wise, and like those vehicles, it provides room for five adults and a goodsized cargo area. The LEAF® is aerodynamically designed for efficiency - equipped with a spoiler, and a flat underbody. Placing the batteries in the floor of the vehicle provides optimum weight distribution to help enhance handling and allows for five-passenger seating by not intruding into the cabin space.

By redesigning the front lower grill, coefficient of drag for 2013 has been improved from last year’s 0.29 to 0.28.

In the rear, the slim-type aerodynamic LED taillight design and crisp corners combine with the aerodynamic rear bumper with rear diffuser to manage the aerodynamics of the rear end.

There are 16-inch steel wheels with full wheel covers on the S grade, 16-inch aluminum-alloy, 5-spoke on the SV, and 17-inch aluminum-alloy, split 5-spoke wheels on the SL trim level.

Headlights

The headlights are aerodynamically shaped to help reduce drag and wind noise. Halogen headlights come with the S model, while the LED headlights are available with SV level trim. The LED headlights come standard with SL models.

Photovoltaic Solar Panel Spoiler

The 12V battery charge control of the high voltage system automatically charges the 12V battery in case the 12V battery voltage is low.

There is an available photovoltaic solar cell module option that is installed on the upper part of rear spoiler. It’s designed as a backup to recharge the 12v system in place of the high voltage system, when there is sufficient solar radiation (sun light).

Interior

The roomy Nissan LEAF® interior offers a pleasingly modern design created to provide a unique “EV touch” with simple, human flow.

Automatic Climate Control System (SV & SL)

The 2013 LEAF® is available with a climate control system that provides superior cold weather performance while consuming less energy.

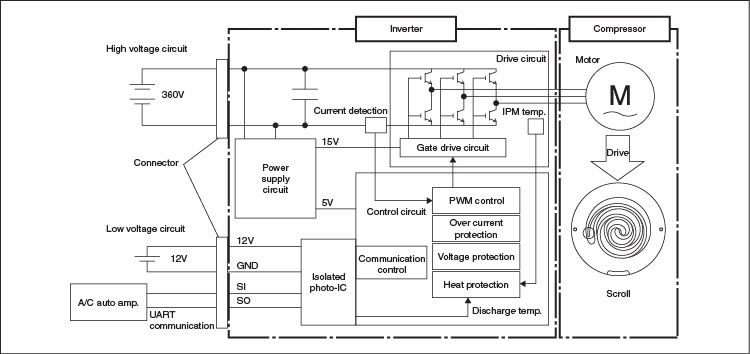

The SV and SL vehicles have a new automatic climate control system called a heat pump. A new A/C compressor is used to either help heat or cool the vehicle’s interior. When in heat mode the refrigerant is used to heat the vehicle and when in cool mode it is used to cool the vehicles interior. this is accomplished by new 2-way and 3-way valves to direct the refirgerant in the system. There is also an inner condensor located in the passenger compartment to heat the air inside the vehicle.

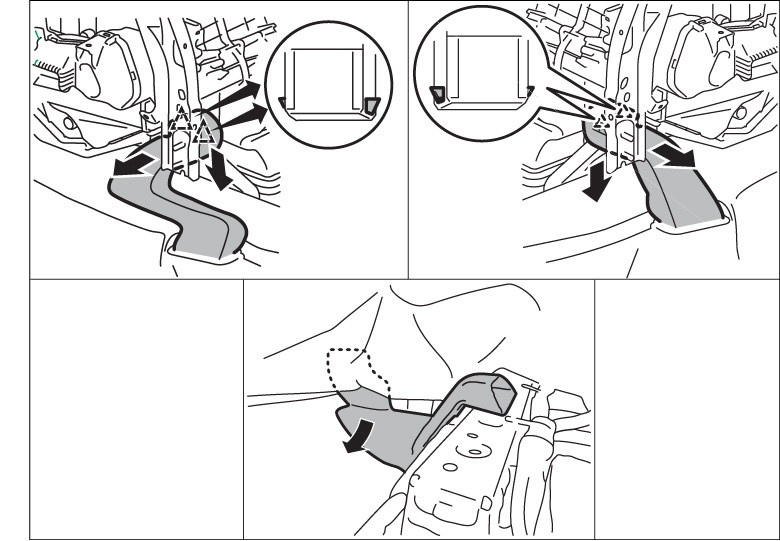

Rear HVAC Ducts

Rear HVAC ducts have been added to the LEAF®. The two supply ducts connect to the front center duct, supplying heated or cooled air to the rear passenger area from under each front seat.

Vehicles without NAVI are equipped with an Automatic Climate Control System.

Enhanced interior features include the addition of Nissan’s Around View Monitor system, and the choice of a leather upholstered interior with a standard leather-wrapped steering wheel to a new black interior color and sun visor extensions. Rear cargo space has been increased to 24 cubic feet with the 2nd row seat upright by relocating the onboard charger to the front of the vehicle. There is 30 cubic feet of cargo space with the standard 60/40-split rear seat folded down.

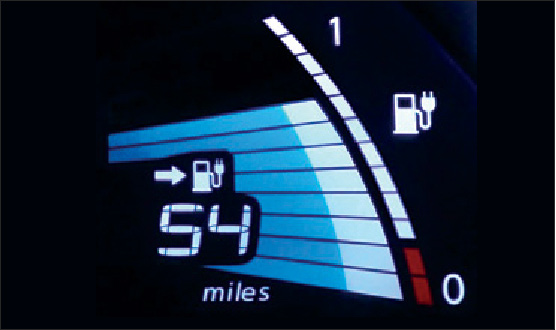

LEAF’s digital instrument panel includes a speedometer, battery temperature gauge, power meter, remaining energy gauge, capacity level gauge, distance to empty display and Eco indicator. A new state-of-charge percentage display has been added to the trip computer. The digital display at the top of the instrument panel provides high visibility for the Eco indicator and speedometer. The lower liquid crystal meter display houses the new percentage style state-of charge meter, power meter, and battery temperature gauge, multi-function display, remaining energy gauge, capacity level gauge and distance to empty display. Vehicles equipped with the Navigation system can also display “reachable area,” as well as showing a selection of nearby charging stations.

All grades include Bluetooth® Hands-free Phone System. A RearView Monitor is optionally available on LEAF® S, while the advanced Around View® Monitor system, which helps provide a virtual 360° view of objects around the vehicle is offered as part of the Premium Package for SV and SL grades.

The Premium Package has an available 7-speaker Bose® audio system.

Recycled materials are being used for the back door trim, roof trim and headliner, carpeting and a number of other interior pieces such as the door panels and center console storage cover. LEAF® SL includes new standard leather-appointed seats for 2013.

The center console area includes the shift-by-wire drive Palm-shifter (inspired by a PC mouse) for the “by wire” drive selector. The standard 3-spoke heated leather-wrapped steering wheel houses controls for the cruise control (except S), audio system and standard Bluetooth® Hands-free Phone System. SiriusXM Satellite Radio (SiriusXM subscription required, sold separately) is also standard, with HomeLink® Universal Transceiver standard on SL models.

The remote keyless entry function can operate all door and rear hatch locks. The charge port door lid may be opened by pressing and holding the charge port unlock button. The panic alarm button will activate the alarm.

As many as 4 keys can be registered and used with one vehicle.

Heated Front & Rear Seats

The front seats and the rear outboard seats can be warmed by built-in heaters. The switches located on the center console and at the side of the front passenger seatback can be operated independently of each other. The heated seat system (Driver side, passenger side and rear seats) consists of heated seat relay, heated seat switch, seat heater and A/C auto amp.

The front seat heater is located inside of front heated seat cushion and seat back, and operates with power source provided via front heated seat switch. The rear seat heater is located inside of rear heated seat cushion, and operates with power source provided via rear heated seat switch. The rear heated seat relay is turned ON when front heated seat relay is turned ON, and supplies power source to rear heated seat.

The heater is controlled by a thermostat, automatically turning the heater ON and OFF. The indicator light will remain on as long as the switch is ON.

The heated seats consumes less power than the heater and can be used to help extend vehicle range by reducing heater use.

When the vehicle’s interior is warmed, or before you leave the vehicle, be sure to turn the switch OFF.

Heated Steering wheel

The heated steering wheel switch is located on the instrument panel to the left of the steering wheel. The heated steering wheel system is designed to operate only when the surface temperature of the steering wheel is below approximately 68°F. When you push the Heated Steering Wheel switch after you start the vehicle, the indicator light will illuminate. The system will automatically turn ON and OFF to maintain a temperature above 68°F. With the power supply from the heated steering wheel relay, the heated steering wheel controls temperature through the heating element and thermostat built into the steering wheel. If the surface of the steering wheel is above 68°F, the heated steering wheel feature will not activate. This does not indicate a malfunction. The A/C auto amp. has a timer. After the heated steering wheel switch is turned ON, when operating time exceeds the specified time (30 minutes), the A/C auto amp. turns OFF the heated steering wheel relay to stop heating.

Comfort and Convenience

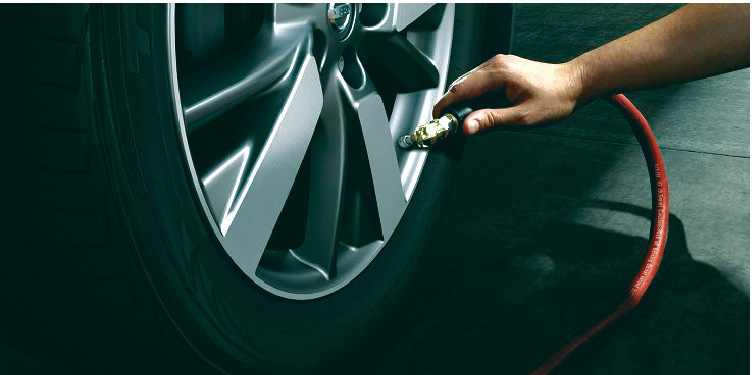

Tire Pressure Monitoring System

The 2013 LEAF® has been equipped with a Tire Pressure Monitoring System (TPMS) that illuminates a low tire pressure telltale when one or more of the tires are significantly under-inflated. The TPMS will activate only when the vehicle is driven at speeds above 16 MPH (25 km/h).

TPMS with Easy-Fill Tire Alert

When adding air to an under-inflated tire, the TPMS with Easy-Fill Tire Alert provides visual and audible signals outside the vehicle to help the customer inflate the tires to the recommended COLD tire pressure. When adding air to the tire after a few seconds, the hazard indicators start flashing. When the tire reaches the correct pressure, the Easy-Fill Tire Alert will sound the horn once and stop the hazard indicators from flashing to indicate the pressure is correct. If the tire is over-inflated more than approximately 4 psi (30 kPa), the horn beeps and the hazard light indicators flash 3 times. If the Easy-Fill Tire Alert does not operate due to TPMS interference, move the vehicle about 3 ft (1 m) backward or forward and try again.

The tire pressure sensors generate a radio frequency (RF) signal to the Remote keyless entry receiver. The I-Key antennas generate a low frequency signal. The BCM uses the triangulated antenna signal to identify the location of each sensor.

The BCM receives a signal transmitted from the tire pressure sensors/transmitters installed in each wheel. If the BCM detects low inflation pressure or a system malfunction, it sends a signal to the combination meter via CAN communication.

Audio and Entertainment

Standard on SV and SL grades is the Nissan Navigation System with NavTraffic (SiriusXM subscription required, sold separately). The EV-IT Navigation system improvements for 2013 include a new “Eco route.” The NAVI also provides access to the CARWINGS telematics system (standard on SV and SL), which is connected to a Nissan data center, (subscription required, no charge for 36 months). With CARWINGS, Nissan LEAF® drivers are able to use mobile smart phones to turn on air conditioning and set charging functions remotely, even when the vehicle is powered down. The on-board charging timer can also be programmed to start the charging event whenever desired. The NAVI system also displays “reachable area” (with available charge), as well as showing a selection of nearby charging stations. This helps to support a zero emission lifestyle with suggested power-saving alternative routes.

A 7.0-inch display is standard on SV and SL grades, and a 4.3” inch color LCD display is standard for the audio unit on the S Grade.

Google Local Search to EV-IT (SV & SL)

Google® local search, Pandora® link for iPhone® and iPod® cover art have also been made available. The new Google Places search function allows LEAF® owners to look for area restaurants, shops and other points of interest and browse user reviews using Google’s POI database to get the most up-to-date information at all times.

Three new option packages are available – offering advanced systems such as Around View® Monitor and 7-speaker Bose® energy efficient audio. There’s also an auxiliary Input Jack and USB Connection Port for iPod® and other devices.

Maintenance

Service Plug

The service plug is included in the Li-ion battery to securely disconnect the high voltage system during high voltage part inspection and maintenance. The service plug is installed on the upper surface of the battery pack. The plug can be removed when the tunnel mounted service plug cover is removed.

![]()

Be sure to remove the service plug in order to shut off the high voltage circuits before performing inspection or maintenance of high voltage system harnesses and parts. Because the LEAF® vehicle contains a high voltage battery, there is the risk of electric shock, electric leakage, or personal injury accidents, or death if the high voltage components of the vehicle are handled incorrectly. Be sure to follow the correct work procedures when performing inspection and maintenance.

- To prevent the removed service plug from being connected by mistake during the procedure, always carry it in your pocket or put it in your tool box.

- Be sure to wear proper insulating protective equipment consisting of glove, shoes, face shield, and glasses before beginning work on the high voltage system.

- Clearly identify the persons responsible for high voltage work and ensure that other persons do not touch the vehicle. When not working, cover high voltage parts with an insulating cover sheet or similar item to prevent other persons from contacting them.

Opening the Battery Case

The 2013 Lithium-ion battery case is now sealed at manufacture with an extruded gasket seal that must be cut open when disassembling the battery case. The J-51052 Gasket Cutter and J-51054 Gasket Cutting Wire special tools are used for this purpose. Carefully cut the seal and then scrape the seal membrane away from the battery pack upper and lower case assembly using the J-51053 Gasket Scraper.

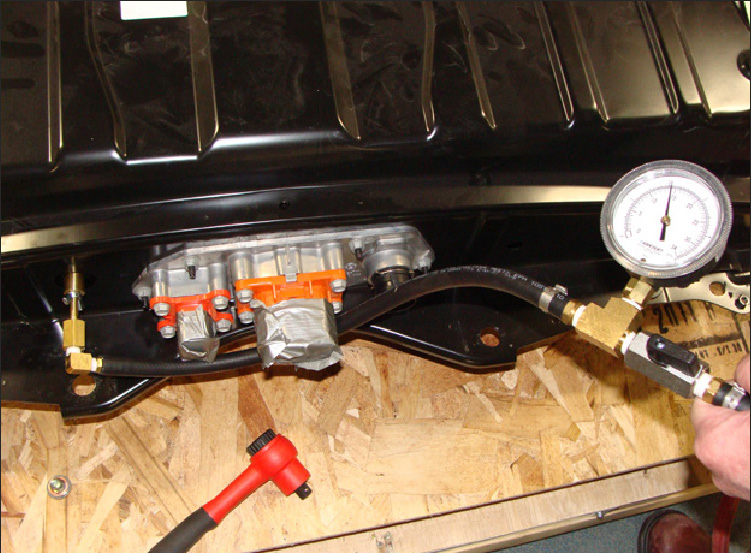

Air leak Inspection

1. Remove the drain plug and install the adapter.

2. Use vinyl tape or similar means to seal the connectors so that air does not escape.

3. Install the service plug to seal the battery pack.

4. Use vinyl tape or similar means to seal the breather so that air does not enter it.

- Use a wide vinyl tape which can cover up breather at once.

- Stick it so that tape is not wrinkled.

5. Perform the air leak inspection using J-51051 Leak Decay Tester.

The pressure reading on the J-51051 Leak Decay Tester should be above 1.4 kPa (0.0142 kg/cm2, 0.203 psi) after 1 minute. If the pressure is below the limit value, check for the locations of air leakage and repair as needed.

Electric Equipotential Test

After assembling the Li-ion battery pack, measure the resistance between the ground bolt mating surface and the high-voltage harness connector flange.

If the results deviate from the standard value, check the following and correct the malfunction. Standard : Less than 0.1Ω.

- Conditions of bonding plate connection

- Corrosion on bonding plate mounting surface

- Presence of paint, oil, dirt, or other substance on the bonding plate mounting surface

Condition of charging port/gun

![]()

Before charging, make sure that there is no foreign material such as water/dust inside the charging port/gun.

- DO NOT touch the charging port with your hands. When connecting in the condition in which there are any foreign materials such as water/dust inside them, earth leakage or electric shock could be caused.

- DO NOT charge when the charging port/gun has any damage, corrosion or rust or there is looseness at the connection part. Earth leakage, electric shock, shortcircuits or fire could be caused.

- Check that there is no irregular wear of the quick charge port lock. If the port is damaged, for example if the metal plate on the inside is lost, replace the quick charge port.

- DO NOT touch the metallic terminal of the charging port/gun. Accidents such as electric shock, etc. could be caused.

- There is a hole on the charge port for water drainage. If the drain becomes blocked, or if water gets trapped inside the charge port, do not charge.

- DO NOT insert or pull out a plug with wet hands, or standing in water, liquid, or snow.

- DO NOT charge when there is a possibility of a lightning strike . A lightning strike may back feed into the charger causing damage and possible personal injury or death.

- DO NOT modify/disassemble the charging cable. Doing so could cause a fire.

- When handling the charging cable, DO NOT pull it forcibly, twist it, drag it, put something heavy on it, or put it close to a heating device.

- DO NOT drop or shock the charging gun.

Trouble while charging

If you notice an unusual odor or smoke coming from the vehicle when charging, stop charging immediately.

![]()

Even if IGN is turned OFF, a cooling fan may run automatically while charging. DO NOT put hands close to the cooling fan while charging. To avoid injury, always disconnect the negative 12-volt battery cable before working near the fan.

After completion of charging

- After completion of charging, be sure to close the charge port cap. If water or dust gets inside the charge port, this may cause a malfunction.

- A vehicle cannot be changed to the “Ready mode” while the charging gun is connected to the charging port. Pull the charging gun out of the charging port in order to change the vehicle to the “Ready mode”.

Charge control

Charging may stop before full charging is complete.

If charging stops mid-charge, you can restart charging by pressing the start button. To stop charging mid-charge, remove the charge connector, charging automatically stops.

The Li-ion Battery’s ability to hold a charge can be affected by how the vehicle is driven, stored, and how the Li-ion battery is charged and also the Li-ion battery temperature during vehicle operation and charging.

Nissan recommends the following driving and charging habits, whenever possible, communicate this information to your customer to help them maximize their battery’s useful life:

Charging Habits

- If possible avoid driving or charging the vehicle under very high ambient outside temperatures.

- Always allow the vehicle and Li-ion battery to cool down after use before charging.

Note:

The power of the Li-ion battery can be checked on the Li-ion battery available charge gauge.

- Trickle charging (120V) is for opportunity charging only and not recommended for regular use. Normal charge uses the charging device (AC 220/240V, 20A) using a SAE J1772 compliant charging device. Minimize the use of public Fast Charge or Quick Charger.

- NISSAN recommends charging the batteries using the long life mode unless the vehicle is going to be driven a long distance.

- If vehicle will not be used for long period of time, NISSAN recommends charging with long life mode.

Long Life Mode

NISSAN recommends charging the Li-ion battery using the long life mode to help maximize the Li-ion battery useful life. The long life mode is set by changing the [% Charge] to [80% Charge] which improves battery Longevity. The indicator light illuminates when long life mode is set to ON. When the long life mode is set the Li-ion battery cannot be charged more than 80%.

Nissan recommends charging the Li-ion battery using the 100% Charge to maximize the driving range of the vehicle when outside temperatures are below 14°F (-10°C). In cold weather, the vehicle automatically determines when to start charging to fully charge the Li-ion battery, even if the Li-ion battery heater operates.

Training

The 2013 LEAF® EV update training course (EVTN2013A_ILT) is required to maintain your LEAF® EV certification. It covers the new features, systems, and service procedures. Refer to the Course Catalogue for more information.