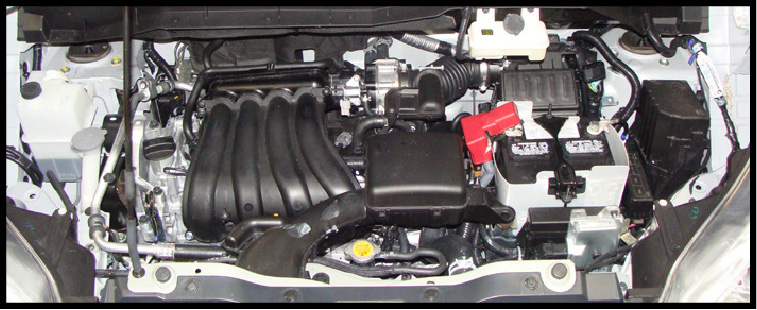

The 2013 Nissan NV200 is built on Nissan’s compact commercial platform and features the proven MR20DE engine, coupled to a responsive and efficient Xtronic CVT®.

Engine

This MR20DE is an efficient 2.0-liter 16-valve DOHC 4-cylinder engine rated at 131 horsepower and 139 lb-ft of torque. Its equipped with an intake valve timing controller (integral with cam sprocket) which continuously adjusts the phase of the intake valves according to driving conditions. This system improves both low/mid range engine torque and high-speed range engine output, which helps to lower fuel consumption and emissions.

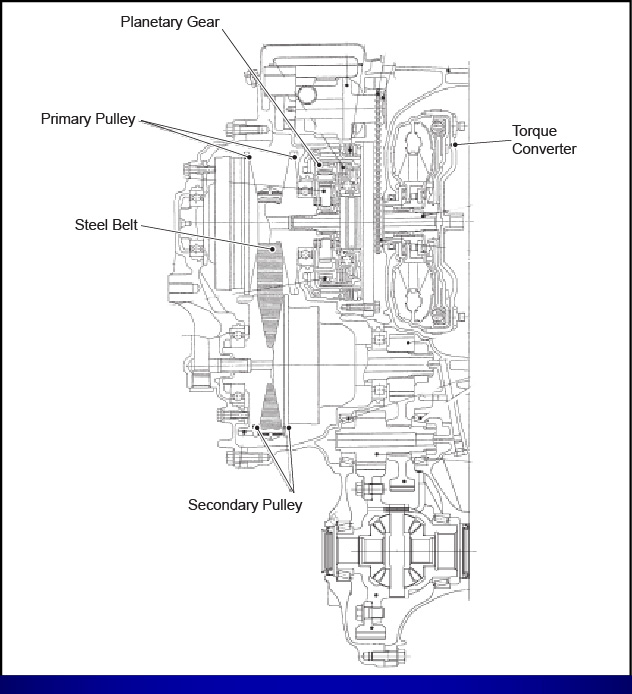

Transmission

The NV200 Cargo van is equipped with the new RE0F10A Continuously Variable Transmission (CVT) for both models. It was designed to provide smooth acceleration and quiet operation. The CVT uses a torque converter, primary and secondary pulleys, a steel belt, planetary gears, and a final drive/differential to provide ratio control and forward and reverse output.

The CV Transmission uses a primary and secondary pulley connected by a high-strength steel belt to transmit engine torque to the front wheels. This setup makes for smooth, un-stepped, “continuously variable” ratios. The primary and secondary pulleys groove widths are controlled by oil pressure. This allows the engine to operate in the optimum power range for a variety of driving conditions by selecting a ratio for every driving situation, continuously changing the ratio as necessary. The RE0F10A CVT incorporates a “planetary gear type mechanism” which is installed between the torque converter and primary pulley. This design is comprised of a carrier, pinion planet, and pinion shaft. The gear mechanism operates by fixing and releasing the planet carrier in order to switch between forward and reverse driving. The power from the torque converter is input via the input shaft, through a planetary gear set to the primary pulley. This then operates a wet multi-plate clutch by means of hydraulic pressure, to switch between forward and reverse driving.

![]()

Using CVT fluid other than Genuine NISSAN CVT Fluid NS-3 will cause deterioration in drivability and CVT durability, and may damage the CVT, which is not covered by the warranty.

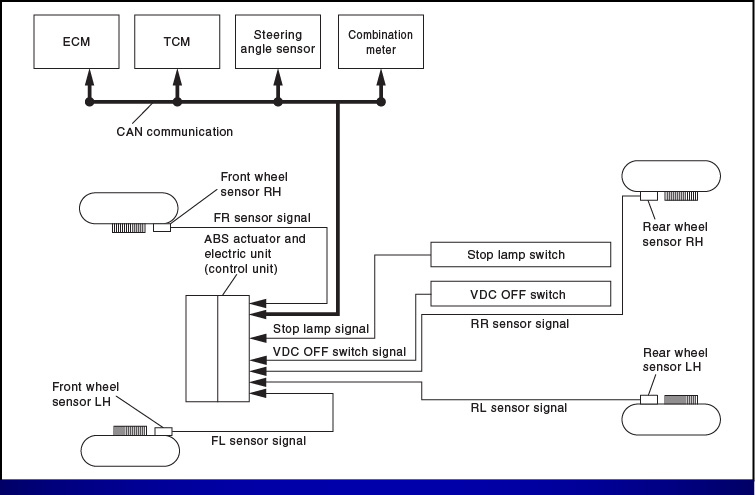

Brakes

The brake system uses 11.14 inch front vented disc and 9 inch rear drum brakes. It comes standard with anti-lock brakes with Electronic Brake Distribution (EBD) and Vehicle Dynamic Control (VDC).

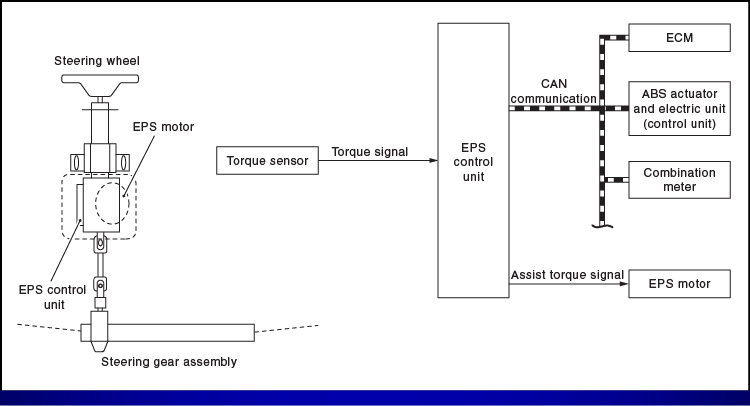

Steering

The NV200 has an electric power assisted steering (EPS) system. The EPS control unit performs an arithmetical operation on data, such as steering wheel turning force (sensor signal) from the torque sensor, vehicle speed signal, etc. It then it generates an optimum assist torque signal which is sent to the EPS motor according to the driving condition.

The EPS system has a fail-safe mode (overload protection control) to protect the system in the event that it becomes overheated. The EPS control unit decreases the output signal to the EPS motor when the power steering function is used consecutively. This protects the EPS motor and EPS control unit. While activating overload protection control, the assist torque gradually decreases, and the steering wheel turning force becomes heavy. The normal assist torque resumes after no steering input is detected for a period of time. In case of an error in the electrical system, the fail-safe function stops output signals to the EPS motor. The previous state is then changed to the manual steering state.

EPS control unit will decrease assistance under the following 2 conditions:

- Extensive steering at low speeds will cause the ECU and motor to heat up. Once the temperature reaches the critical point, the ECU will reduce the current to reduce heat build-up. The system will recover as temperature lowers (reduced or no assistance).

- Holding the steering wheel at full lock for 1 second will cause the system to engage rack-end protection. This reduces assistance down to 50% in order to prevent heat up. Assistance is immediately returned to 100% when the steering wheel is released or turned away from full lock.

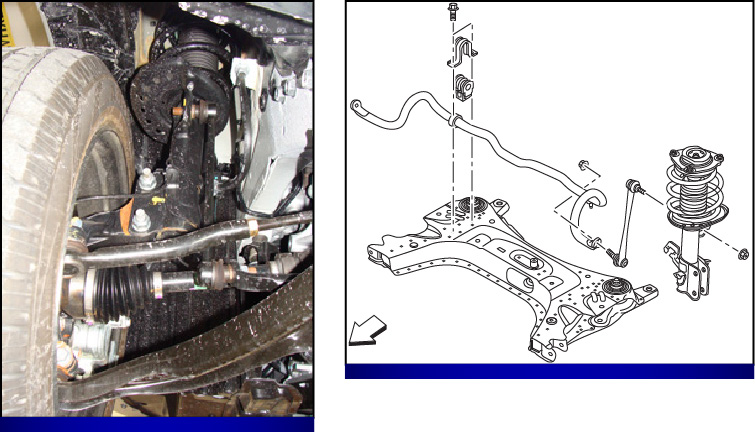

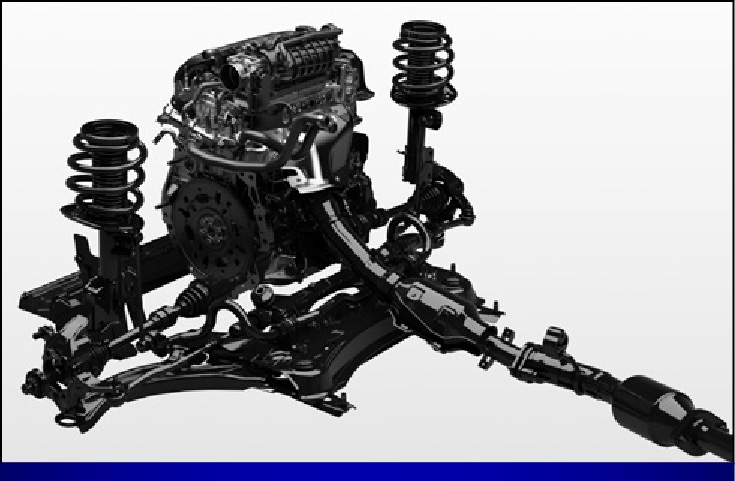

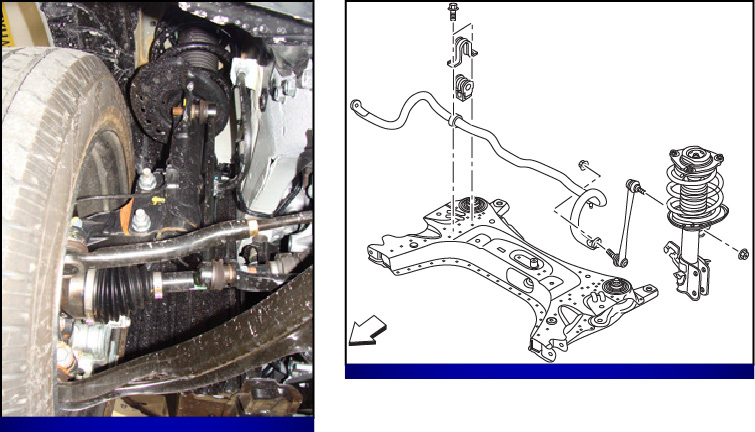

Front Suspension

The NV200 Cargo van has an independent front strut suspension system. When aligning the NV200, the only adjustment is toe-in. Camber, caster, and kingpin inclination angles cannot be adjusted. It is also equipped with a front stabilizer bar to minimize body roll.

Rear Suspension

The rear suspension does not require periodic alignment because it utilizes a rear beam axle design with rigid leaf springs positioned over the rear axle.