The engine system on the 2015 Murano® includes new features and functions.

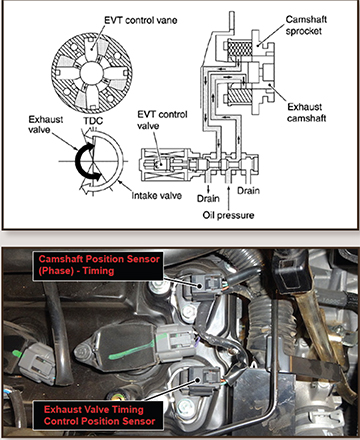

The 3.5-liter VQ35DE engine includes both Variable Intake and Exhaust Valve Timing Control. Intake and exhaust valve position sensors are located on top of the camshaft covers of each bank. These sensors monitor the exact position of the camshafts and provide a signal to the ECM. Intake and exhaust valve time is adjusted using engine oil pressure and a series of oil control valves controlled by the ECM. They provide intake and exhaust valve timing advance or retard depending on driving conditions.

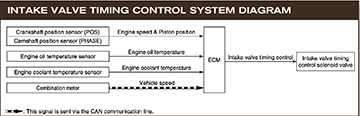

The ECM monitors crankshaft and camshaft positions, engine speed, coolant temperature and other signals to determine if intake valve timing adjustment is required. The ECM sends a pulse-width modulated signal to the oil control valve to advance, retain, or retard the intake valve timing to increase engine torque in low/mid speed range and horsepower output in high-speed range.

INTAKE VALVE TIMING INTERMEDIATE LOCK

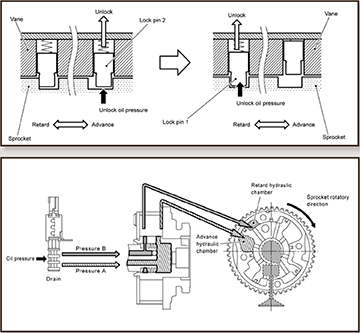

The purpose of the intermediate lock function on the variable intake valve timing control system is to lock the intake camshaft sprocket in the intermediate position during cold engine starts. Locking the sprocket in this position helps reduce cold-start emissions. The intermediate lock system uses two spring-loaded lock pins that hold the sprocket in the intermediate position. Lock pin 1 controls the retard position and lock pin 2 controls the advance position. When coolant temperature rises, the intake valve timing intermediate lock control valve solenoid is energized and oil pressure pushes the lock keys outward to unlock the sprocket, allowing variable timing control.

VARIABLE EXHAUST VALVE TIMING CONTROL

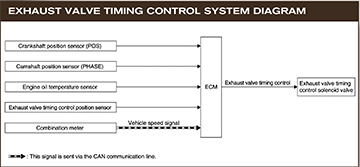

The variable exhaust valve timing control system works on the same hydraulic principle as the variable intake valve timing control, but does not include the intermediate lock components. The ECM can adjust exhaust valve timing by varying the pulse width signal to the exhaust valve timing control valve solenoid. Increasing exhaust valve timing retard at higher engine speeds results in greater intake exhaust valve overlap, allowing additional high RPM performance. The system on the Murano starts to retard timing at much lower speeds than on other vehicles with variable exhaust valve timing.

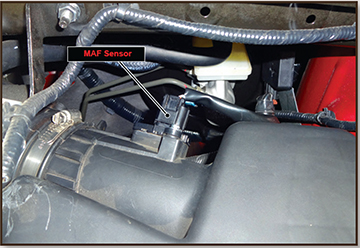

MASS AIR FLOW SENSOR (WITH INTAKE AIR TEMPERATURE SENSOR)

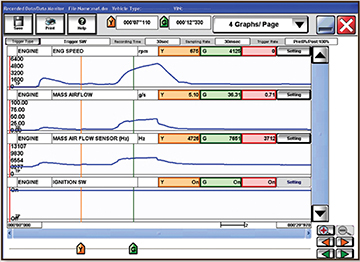

The new Mass Air Flow (MAF) sensor is located on the air induction tube between the air filter and throttle body. The intake air temperature sensor is built into the MAF. Placed in the stream of intake air, it measures the intake flow rate as the intake air flow increases. The temperature distribution around the heater changes according to the increase in intake air volume.

The sensor detects intake air temperature and transmits a signal to the ECM by the MAF sensor. The ECM translates the signal into intake air flow data. The new MAF sensor is a four-wire design instead of the five-wire design used on previous Muranos. When diagnosing the MAF sensor data with CONSULT-III plus, the specifications are now provided in grams per second and hertz instead of volts.