LOOSE FUEL CAPS

The fuel cap on all Nissan and Infiniti vehicles is an integral part of the EVAP system. It must be installed correctly or the EVAP diagnostic system will detect a fault.

To correctly install a fuel cap on all

late model Nissan and Infiniti vehicles, it must be turned

in a clockwise direction until a click is heard. At times,

a customer may stop turning just before the click. If this

occurs, the cap is not installed correctly. It will be loose,

causing a leak in the EVAP system.

The fuel cap is removed and

then reinstalled with each fill up; combine that with the millions

of Nissan and Infiniti vehicles on the road and we are bound to have

a fuel cap left loose now and then.

As of the 2012 model year, all

Nissan and Infiniti vehicles have a warning message that alerts the

driver when a fuel cap has been left loose.

Note:

The basic ECM logic for a Loose Fuel Cap warning message is:

- The fuel tank was refilled (fuel level increased) since the last leak test.

- EVAP system now has a leak.

- Conclusion, fuel cap was left loose.

- Loose Fuel Cap warning message is turned ON.

Delay between fuel fill (loose cap) and warning message:

- Due to the various conditions that are required for the EVAP system to perform a leak test, it may take a few driving trips for the Loose Fuel Cap warning message to display.

What to do:

Loose Fuel Cap Causing an MIL with a DTC

From time to time, a vehicle may be presented to the dealer with the MIL ON, but the customer has not reported leaving the fuel cap loose. In this case, you will likely, find one or more of the following DTCs stored:

P0442 - EVAP CONTROL SYSTEM SMALL LEAK DETECTED

P0455 - EVAP CONTROL SYSTEM GROSS LEAK DETECTED

P0456 - EVAP VERY SMALL LEAK

Although the most likely cause of these DTCs is a fuel cap that is or was loose, you still need to perform some diagnostics to make sure the EVAP system does not have a leak.

The basic diagnostic for this situation is:

- Confirm the fuel cap is installed correctly.

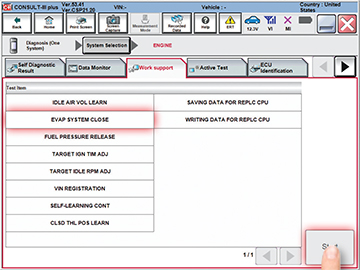

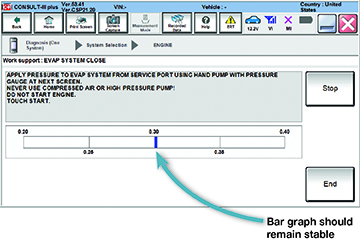

- Use CONSULT-III plus > Engine > Work Support > EVAP System Close > Start the leak test.

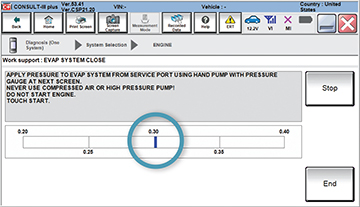

- Connect Essential Tool J-42909 to the EVAP service port.

- Apply pressure using J-42909 until the bar graph reaches about halfway.

- Monitor the bar graph for 10 minutes.

- No EVAP leak is detected at this time.

- MIL ON is due to a loose fuel cap.

- Erase DTC(s).

- Advise the customer that the fuel cap ALWAYS needs to be correctly installed.

- EVAP leak is detected.

- Refer to ASIST® and the appropriate ESM for further diagnosis, testing and repair.

If the bar graph remains stable:

If the bar graph drops:

Smoke Machine

A separate piece of test equipment, commonly called a "smoke machine," can also be used to help

test the EVAP system for leaks.

There are several manufacturers of "smoke machine" leak

detectors; they all work similarly. Here we will show the use of the LiB Leak Decay Tester

(625-WV608), which is part of the required special tool kit for LEAF-certified dealers.

Note: This machine can be purchased separately from TECH-MATE (1-800-622-2001).

Smoke Machine Test Steps

- Connect the air line from the tester to the vehicle's EVAP service port.

- Connect the tester power supply.

- Connect the shop air supply hose to the tester.

- Adjust the flow control to allow pressure into the EVAP system until the bar graph on C-III plus is about 1/2 and the gauge on the smoke machine reads about +10 inches of water.

- Turn the flow control to OFF.

- Watch the bar graph on C-III plus for about 10 minutes.

Important:

- Due to the various conditions that are required for the EVAP system to perform a leak test, a test drive is not a helpful diagnostic step.

- Test driving the vehicle for these DTCs will only waste time.

- It is likely that a loose cap, and not a malfunctioning cap, is the cause of DTCs mentioned in this article.

- Before replacing any parts, confirm the malfunction using diagnostic procedures in the ESM.

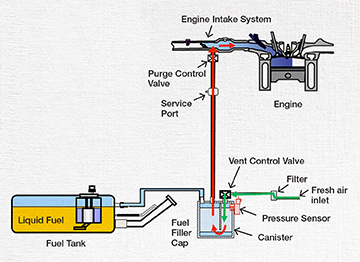

Basic EVAP System Operation

- Fuel vapor flows from the fuel tank into the canister (light blue area).

- Vapor flows from the canister through the purge control valve (red line).

- Fresh air flows into the canister (green line).