The Li-ion battery modules are built at the Smyrna production plant’s new battery production facility.

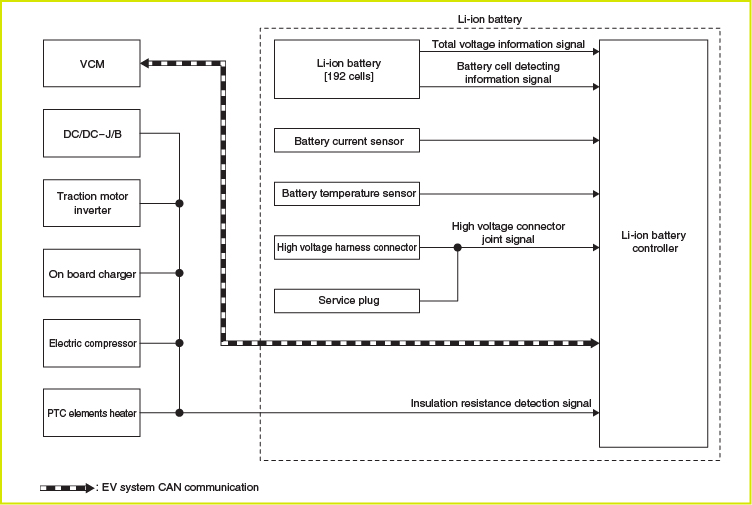

Internal changes to the Li-ion battery have reduced the weight by 44 pounds. These changes include the elimination of the junction box cover and separate module spacers and brackets. A new method for monitoring total battery output that calculates the total output voltage from the sum of all cell output voltages eliminates the total voltage sensor circuit.

Simplified construction also eliminates the need for two different modules with separate part numbers.

Service Points

The Li-ion battery module replacement procedure has not changed significantly.

The gasket between the upper and lower battery cases has been eliminated. There is a new sealing procedure from the previous generation lithium-ion battery case. As with the PDM, an air-tight test must be performed after resealing the cases.

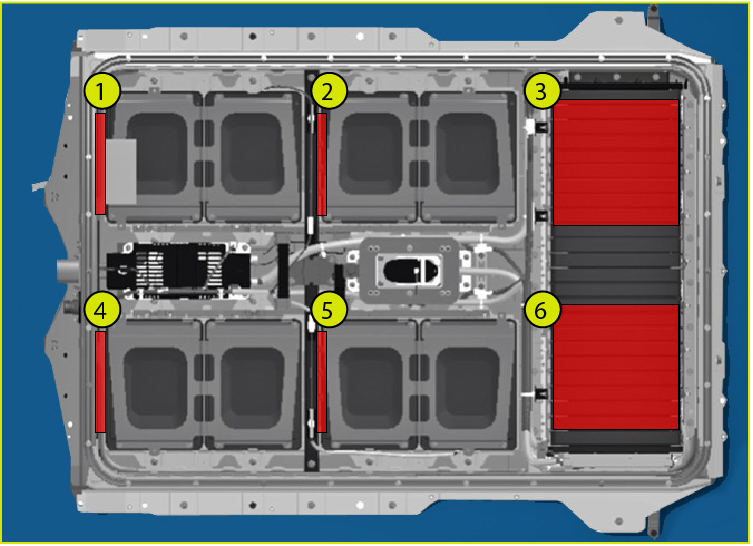

When replacing a module in the front stack, carefully position it to connect the terminals to the bus bar.

Some modules in the rear stack have attached mounting brackets, so you must correctly identify them if replacement is required.

The new module will not fit in the original cradle for the GRX5000 module charge balancer. A new cradle was developed specifically for use with the new module.

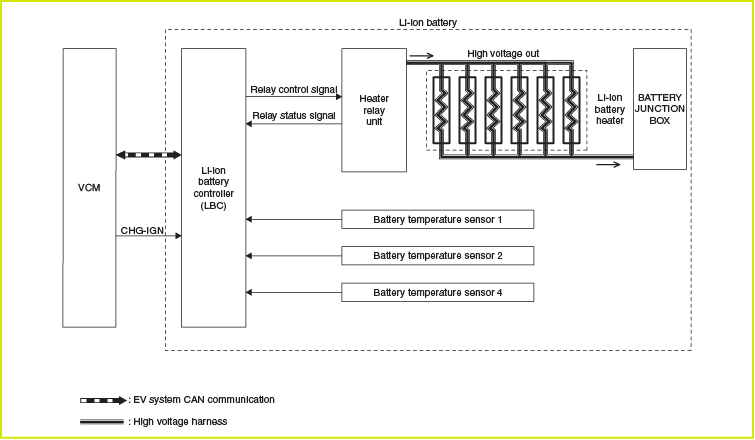

PTC Heaters

The number of PTC heater elements in the battery system has been reduced from 10 to 6. The battery heater system activates if the internal temperature of the battery drops to 1.4°F instead of at the previous temperature of -4°F. The battery heater system still operates until the internal battery temperature reaches 14°F or until the battery state of charge (SOC) drops to 30%.