Mechanical

Engine

The 2013 JX is equipped with a VQ35DE 3.5-liter DOHC 24-valve V6 engine from the acclaimed VQ series. This transverse-mounted engine was designed to provide outstanding response, performance and economy. The JX35 is equipped with this large-displacement engine design to provide more power (especially when accelerating and passing), which helps reduce engine stress by allowing the engine to work efficiently at any given speed.

The standard Double overhead cam (DOHC) engine is rated at 265 horsepower @ 6,400 RPM and 248 lb-ft of torque @ 4,400 rpm. The VQ35DE includes a Variable Induction Control System to help improve volumetric efficiency by utilizing front and rear power valves assemblies in the intake manifold.

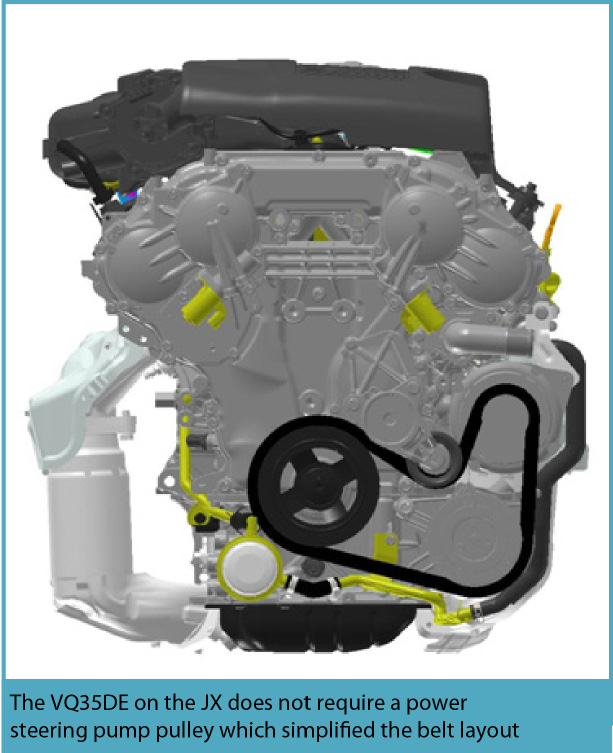

The JX has a new more efficient belt layout that will simplify maintenance and help fuel economy. Fuel economy is rated at 23 mpg highway, 17 mpg city and a real-world 19 mpg rating combined – while still offering the power to carry a full load of passengers and cargo.

NOTE: Drive belt tension is not manually adjustable. The drive belt tension is automatically adjusted by the drive belt auto-tensioner.

The JX's engine includes a lightweight aluminum-alloy block, pistons and connecting rods, as well as a compact crankshaft. Its Variable Valve Timing (CVTCS) variable induction control system helps to improve volumetric efficiency over the entire engine speed range by employing sophisticated electronics to control valve timing and throttle response.

All models are certified to comply with low-emissions regulations in many states, permitting their sale and registration in any of the 50 states. For the specific vehicle emission classification, see the emission control label located under the hood.

Electronic Sequential Multi-Point Fuel Injection

The JX utilizes electronic sequential multi-point fuel injection to enhance its overall drivability. This helps improve hot and cold starting capability by injecting precise quantities of fuel at exactly the right moment in relation to valve timing and piston position.

The new JX is equipped with Front and Rear engine mounts that are electronically controlled and liquid-filled. Vacuum levels in the engine mounts are regulated by a vacuum solenoid.

Xtronic CVT (Continuously Variable Transmission)

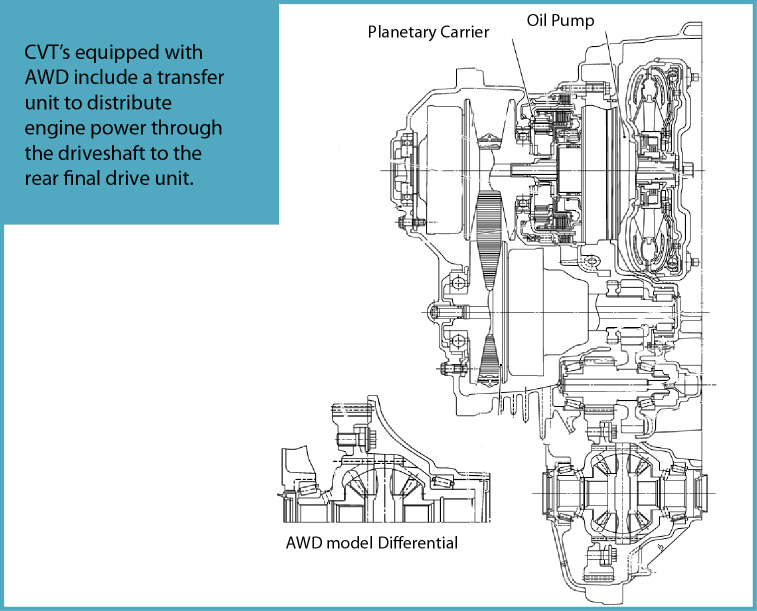

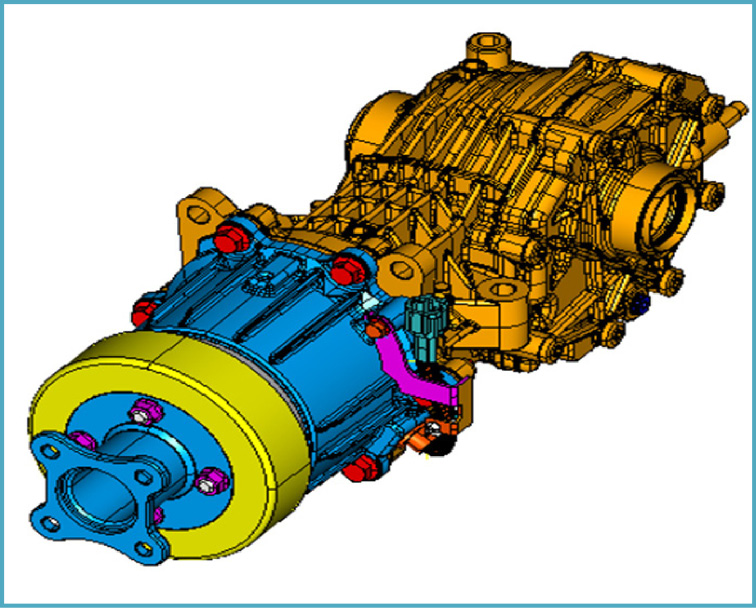

The JX is equipped with the new RE0F09B Continuous Variable Transmission (CVT) for both AWD and FWD models. It was designed to provide smooth acceleration and quiet operation. The CVT uses a torque converter, primary and secondary pulleys, a steel belt, planetary gears, and a final drive/differential to provide ratio control and forward and reverse output.

The CV Transmission uses a primary and secondary pulley to transmit engine RPM to the front wheels by using the high-strength steel belt that operates between the two continuously adjustable pulleys. The groove width changes according to the wrapping radius of steel belt and pulley and varies from low status to overdrive status continuously with no-step. The primary and secondary pullies groove widths are controlled by oil pressure. This allows the engine to operate in the optimum power range for a variety of driving conditions by selecting a ratio for every driving situation, continuously changing the ratio as necessary. It incorporates a "planetary gear type mechanism" which is installed between the torque converter and primary pulley. This design is comprised of a carrier, pinion planet, and pinion shaft. The gear mechanism operates by fixing and releasing the planet carrier in order to switch between forward and reverse driving. The power from the torque converter is input via the input shaft, through a planetary gear set to the primary pulley operating a wet multi-plate clutch by means of hydraulic pressure, to switch between forward and reverse driving.

Oil Pressure System

New Oil pump

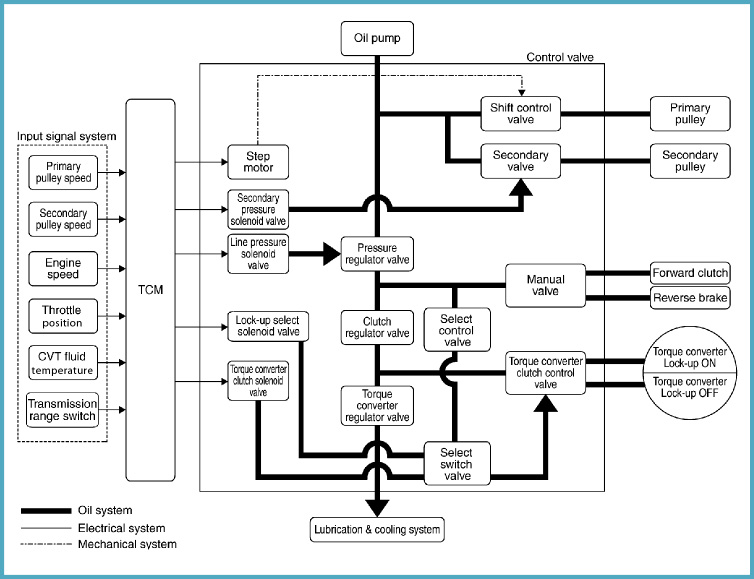

The oil pressure required for operation of the transaxle transmission mechanism is generated by the oil pump, oil pressure control valve and solenoid valve.

The RE0F09B for the JX adopts a trochoidal oil pump with a flow control valve actuated directly by the engine. This design enables the sufficient discharge from the oil pump in the low-rpm range and provides for adequate discharge adjustments in the high-rpm range. Discharged oil from the pump is controlled by the control valve. The discharge oil is used for primary and secondary pulley operation, the oil for clutch operation, and the lubricant for each part. The flow control valve provides highly accurate line pressure control and secondary pressure control which helps reduce friction for improved fuel economy.

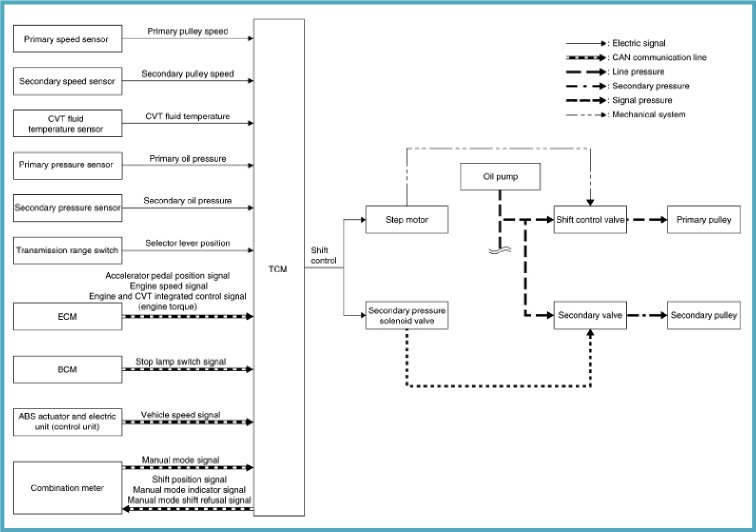

The control of line pressure and secondary pressure required for the driving condition is determined by input from: accelerator pedal position, engine speed, primary pulley (input) speed, secondary pulley (output) speed, input torque, stop lamp switch signal, transmission range switch signal, lock-up signal, power voltage, target shift ratio, oil temperature and oil pressure.

Secondary Pressure Feedback Control

To perform normal oil pressure control, and oil pressure control during shifting, highly accurate secondary pressure is determined by using an oil pressure sensor, and by feedback control.

When shifting between "N" ("P") and "D" ("R"), the operating pressure is optimized on the basis of throttle position, engine speed and the secondary pulley (output) revolution speed, which in turn helps to lessen the shift shock.

Select Control Valve

The JX transaxle changes gear ratios through a stepper motor controlled by the Transmission Control Unit (TCU). The stepper motor linkage moves the Shift Control Valve to adjust hydraulic pressure at the primary pulley. The Shift Control and Secondary valves hydraulic pressures determine pulley diameters and gear ratios. This precise control enables the transmission gear ratios to immediately adjust to engine load and driving conditions.

![]()

Use only Genuine NISSAN CVT Fluid NS-3. Do not mix with other fluids.

Using transmission fluid other than Genuine NISSAN CVT Fluid NS-3 will damage the CVT, which is not covered by the warranty.

Infiniti Drive Mode Selector

With the Mode Selector the driver can choose between Standard, Snow, Eco, and Sport modes. This system controls throttle response and transmissions shift point characteristics, also AWD control (Snow mode, AWD models only). Drive Mode Selectors on vehicles equipped with the available Driver Assistance Package, also control the Eco Pedal.

The Standard mode is recommended for normal driving mode. This mode automatically selects the shift schedule by considering the balance of fuel economy and driving performance based on the driving condition and driving trend.

The Sport mode adjusts the engine and transmission points to enhance performance. When the Sport mode of the Infiniti drive selector is engaged, the transmission can mimic a step transmission. This mode uses a shift schedule that mainly utilizes the high engine speed zone to improve the driving control characteristic and response.

The Snow mode should be used on snowy roads or slippery roads. When the Snow mode is activated, engine output is controlled to avoid wheel spin.

ECO mode adjusts engine and transmission points to help keep the engine speed at lower levels enhance fuel economy by decreasing needless acceleration and deceleration. If equipped with ECO pedal, the pedal effort may be increased to help the driver stay within the ECO zone.

NOTE: When the drive mode select switch selects a mode, the mode may not switch quickly. This is not a malfunction.

New AW D Unit

Rear Final Drive Assembly

The rear final drive unit on the JX vehicles equipped with an AWD is based on the Murano with the addition of a torsional damper on the input flange for reduced NVH. The case opens from the side access for servicing gears.

The coupling capacity was increased to handle the heavier vehicle weight and higher torque input of the JX to allow for increased towing capacity.

With the vehicle weight increase, larger torque conversion is required. To achieve increased torque conversion on the JX, an electric controlled coupling was integrated with rear final drive.

Disassembly/Assembly, Repairs and Maintenance

There is not enough room to remove electric controlled coupling on vehicle. If electric controlled coupling requires replacement, remove the rear final drive assembly to service the coupling.

When replacing AWD control unit, rear final drive assembly and/or the electric controlled coupling; it is required that you write the unit characteristics of electric controlled coupling with CONSULT to the AWD control unit.

Note: The rear final drive unit uses Genuine NISSAN Differential Oil Hypoid Super SS API GL-5, 75W-90.

Suspension

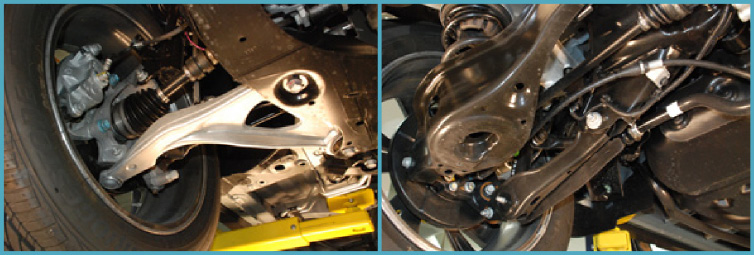

The Infiniti JX has an independent strut front and multi-link rear suspension that includes front and rear stabilizer bars.

Steering

Hydraulic Pump Electric Power Steering

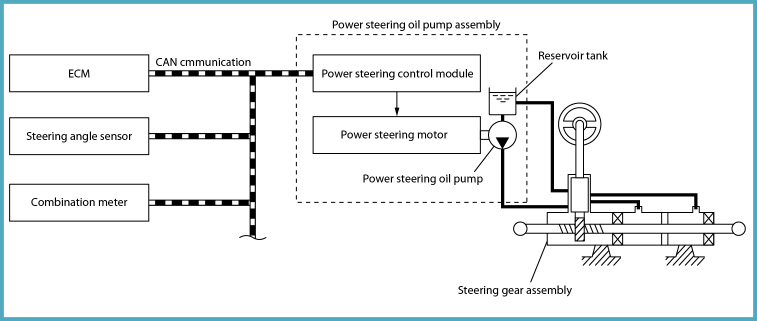

The new JX utilizes a Hydraulic Electric Power Steering (HEPS) system. The system is smaller than traditional power steering systems, which was achieved by integrating multiple parts. Primary components of this system are: PS Oil Pump Assembly (includes PS C/U & PS motor), Steering Angle Sensor, Engine Control Module, Combination Meter, and PS Gear Assembly, and Torque Sensor.

Power to the hydraulic pump of the electro-hydraulic power steering system is delivered by an electric motor and not the engine directly. This means engine load does not change when speed increases, because power is being delivered by the battery and electric motor. With the HEPS the electric motor operation is controlled by the Engine Control Module via CAN communication for precise monitoring of steering force, vehicle speed and steering angle.

The hydraulic electric oil pump operates when the engine starts. The ECM controls the hydraulic pressure transmitted from the power steering motor to power steering oil pump, based on the input it receives from the steering angle sensor and combination meter. When the steering angle speed is low or the vehicle speed is high, the system lowers the hydraulic pressure and reduces the steering assist force. Higher hydraulic pressure is applied when the vehicle speed is low or when the steering operation angle speed is high. The system raises the hydraulic pressure, which increases the steering assist force.

Important HEPS Function Information

• If the steering wheel is operated repeatedly or turned all the way continuously while parking or driving at a very low speed, the function of the hydraulic pump electric power assist steering system will become limited to help prevent the system from overheating.

If a customer continues to perform steering wheel operation while the power assist is reduced, the hydraulic pump electric power steering system may stop. This is not a malfunction. While the power assist is reduced, steering wheel operation will become temporarily heavy in a manual state, and the hydraulic pump electric power steering warning light will illuminate to warn that the system is in the manual state. Turning the engine OFF with the ignition switch in the OFF position allows the temperature of the hydraulic pump electric power steering system to lower and allow the power assist level to return to normal. When the engine is started again, the hydraulic pump electric power steering warning light will go off.

NOTE: With a conventional-type steering assist, the steering pump is powered by the engine. Operational noise increases and is masked as engine speed increases. However, with the Hydraulic Pump Electric Power Steering system, normal operation noise increases and may be heard above engine noise from the engine compartment when vehicle speed is low and steering operation angle is high.

This is because the rotating speed of the hydraulic electric pump increases in order to provide the required steering assist force at lower engine RPM.

By providing power assist via hydraulic electric pump pressure, this system delivers a naturally smooth steering feel due to the flexibility of control allowed by electric power. This system allows more precise steering power characteristics. It also improves fuel economy since the electric powered pump operates only when steering assist is needed.

NOTE: The HEPS requires the use of Genuine NISSAN E-PSF. If another power steering fluid is used, it will prevent the power steering system from working properly and may seriously deteriorate the system's ability to produce steering assist force. Always check the fluid while the engine is stopped.

Brake Control and Available Technology

Intelligent Brake Assist (IBA) with Forward Collision Warning (FCW)

The Intelligent Brake Assist (IBA) system warns the driver with a vehicle detection indicator and chime when there is a risk of a collision with the vehicle ahead in the traveling lane. The system functions to help reduce the rear-end collision speed by applying the brakes when it judges a collision cannot be avoided.

The Forward Collision Warning (FCW) system uses the ICC Distance radar sensor from the IBA system to continuously monitor and analyze closing speeds to a vehicle or a stationary obstacle ahead. The ICC Distance Radar sensor detects the distance to a preceding vehicle and the relative velocity.

When the appropriate driver assistance systems are turned ON, the vehicle assists the driver's braking action according to the situation. IBA helps avoid rear-end collisions, and it also works in concert with the Brake-Operated Pre-crash Seat belts. IBA can sense an imminent collision and will provide a two-stage warning to the driver as the vehicle moves toward impact. If the driver does not respond adequately to both consecutive warnings and a collision can no longer be avoided, IBA will automatically engage the brakes to help mitigate damage and reduce the speed of a collision. The IBA system shares component parts and diagnosis with the Intelligent Cruise Control (ICC) system.

Brake Assist (with a preview function)

The system determines when emergency braking is needed based on the distance to the followed vehicle and relative velocity. The system pre-pressurizes the braking system to help quicken braking response.

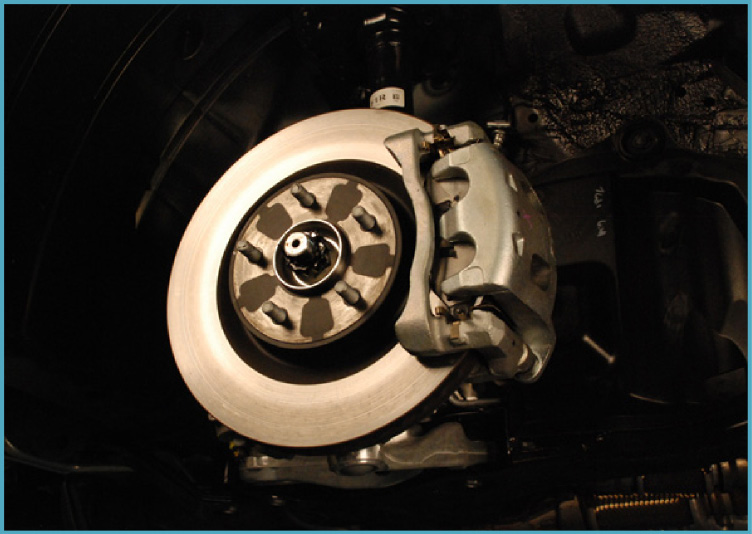

Brake System

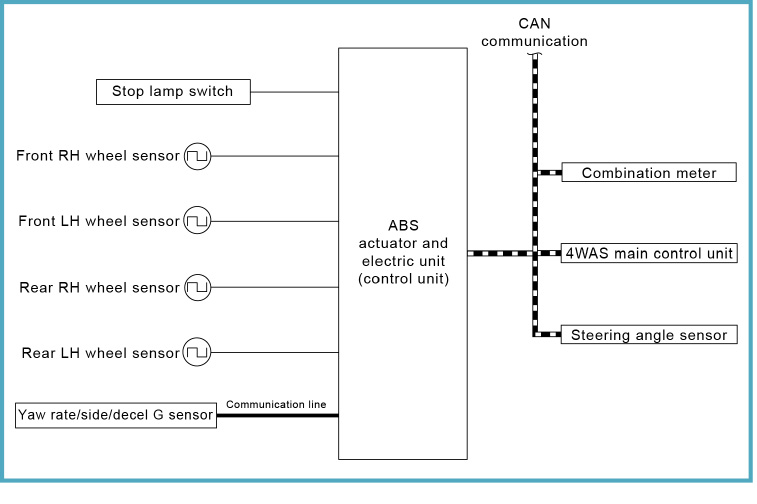

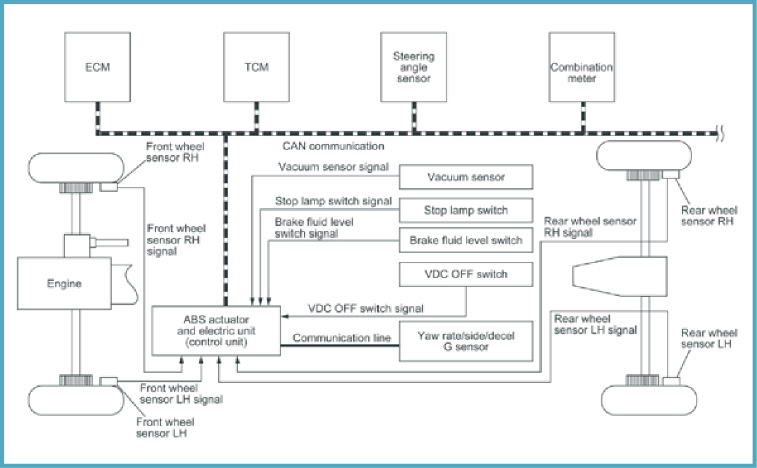

The Infiniti JX can be equipped with the following brake control related systems: Brake assist, and 4-wheel, 4-channel Anti-lock Braking System (ABS) with Electronic Brake force Distribution (EBD). It comes standard with Vehicle Dynamic Control (VDC) that uses various sensors to monitor driver inputs and vehicle motion under certain driving conditions.

1. EBD and ABS function reduces wheel lock-up by controlling the brake fluid pressure to the wheel calipers. If a brake control system malfunction occurs, the system goes into a fail-safe mode suspending the functions of VDC, Traction Control System (TCS), ABS, EBD, Hill start Assist, brake force distribution and Active Trace Control (ATC). The vehicle status will become the same as a vehicle without VDC. CONSULT can be used to diagnose the system.

2. The Infiniti JX also includes a Traction Control System (TCS), to help enhance drive-wheel traction when accelerating. The TCS senses wheel spin at all speeds and automatically reduces power to help limit wheel slip. Engine TCS function reduces wheel slip by communicating with the powertrain controllers to limit the drive torque generated.

3. The Brake TCS function reduces wheel slip by controlling the brake fluid pressure to the wheel caliper.

4. The Brake Limited Slip Differential (BLSD) function equalizes the left-to-right driven wheel speeds by applying brake fluid pressure to the wheel caliper for a spinning wheel that is slipping.

5. The JX comes standard with Vehicle Dynamic Control (VDC). VDC uses various sensors to monitor driver inputs and vehicle motion under certain oversteer and understeer driving conditions. The VDC function helps the JX to control brake pressure and automatically adjust engine output, and will apply the brakes individually as necessary, to help the driver remain on the steered path.

6. The Hill Start Assist (HSA) function on the JX maintains brake fluid pressure on slopes for approximately two seconds so that the vehicle does not move backwards. HSA functions between the time the brake pedal is released and the accelerator pedal is depressed while the vehicle is on an uphill slope.

Driver Assistance

The Driver Assistance systems on the JX include the combination of the Active Trace Control and Brake Force distribution functions aimed to smooth the vehicle movement.

Active Trace Control

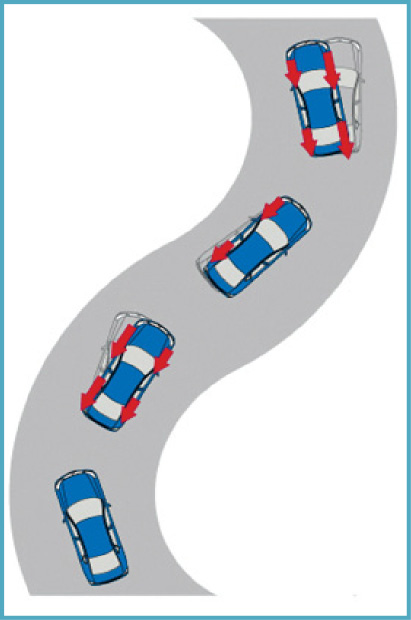

Active Trace Control functions to adjust engine torque and the control of braking at each of the four wheels to help enhance cornering performance. The advanced Active Trace Control system, which is included with the JX Technology Package helps to enhance the transition from braking into and then accelerating out of corners.

During braking, the Brake Force Distribution function optimizes the distribution of brake force to each of the four wheels, depending on the state of the turn detected by driver's steering inputs and some sensors. The system utilizes the JX's VDC system to help improve cornering feel by automatically applying the brakes so that load is increased on the front wheels. The system also modulates engine torque. The Active Trace Control system also applies selective braking to help enhance cornering feel.

For example, if the vehicle is being driven through an S-turn that starts with the customer steering to the right, the right-side brakes are engaged to create a yaw moment and help turn the vehicle. When the vehicle is steered back to the left, left-side brakes are engaged.

The active trace control function can be switched to ON/OFF status by operating the VDC OFF switch. When Sport mode is engaged (on the Infiniti Drive Mode Selector), the level of braking applied by this feature is reduced.

The TCS, VDC and BLSD can be switched to a non-operational status OFF, by switching the VDC switch. When the brake functions are turned OFF, the indicator lamp turns ON.

The Anti-Lock Braking System (ABS), Electronic Brake Force Distribution (EBD), Vehicle Dynamic Control (VDC), Brake Limited Slip Differential (BLSD), Traction Control System (TCS), Active Trace Control (ATC) and Hill Start Assist (HSA) are the same as Infiniti M.

NOTE: CONSULT Diagnosis on the JX, (DTC's, Active Test, Data Monitor, Work Support, etc.) for the brake functions are the same as the 2012 Infiniti M.