![]()

Nowadays, some tire and wheel applications can be a challenge to work with. It takes focus and know-how to avoid costly damage to the tire and/or the wheel and pressure sensor. Tire mounting and even tire inflation can be dangerous!

This article will cover tire machine usage to help you stay out of trouble and do it right the first time. Use of the proper tools and safety equipment and performing the specified procedures correctly will be covered.

Tire Design’s a Changing

Tire design has come a long way. Greater horsepower to the wheels and ABS brake systems have not only improved acceleration and braking; they have also required tire design changes. Today’s tires are designed with tighter safety beads and closer bead-to-rim clearances. Tighter beads help prevent tire slippage at the rim during hard acceleration and severe braking or when tire pressure is low.

Note: The use of tires other than those recommended or the mixed use of tires, construction, or tread patterns can adversely affect the ride.

Nissan Original Equipment Alloy or Genuine Accessory wheels

Because of current styles and for better handling, wheels are getting bigger. There are a multitude of taller performance rims and tires available today. Some customers buy them to get a wider, better grip on the road and enhanced handling performance for their vehicles. Or, they buy them to fill out the wheel wells and just plain look good! If wheels are changed for any reason, always replace them with wheels which have the same off-set dimension.

NOTE: Nissan Original Equipment or Genuine Accessory Alloy wheels, along with their finish coating (clear, chrome, titanium, etc.), are specifically developed to achieve Nissan design and performance standards.

Any damage to the inside or outside of a rim created during service with a traditional tire changer will be noticed by the customer. Replacing a set of wheels damaged during service can be very costly.

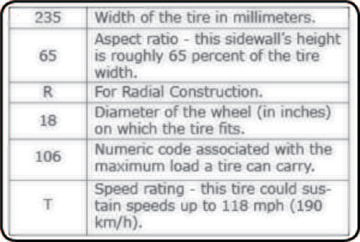

How to Read a Tire Sidewall

NOTE: Some size designations may be preceded by a “P,” signifying Passenger.

Tire Removal and Reinstall Quick Tips

Tires can be damaged if they are not mounted properly. If there is not enough lubricant used or if a tire is not positioned correctly on the rim, tire bead damage may happen. If the bead isn’t fully seated, or if you are trying to over inflate a tire to try and seat the bead, it may lead to problems, or service returns (come backs).

Understand your equipment: One way to avoid wheel/tire service mistakes is to understand that there are now different techniques required for handling today’s tire size and rim combinations. It is a good practice to pay attention to the details of the tire and wheel specifications. Having the proper tools and the correct tire mounting equipment, making sure that your equipment is in good condition, and you understand how to use your tire changer, is a must. Read the Operating Instructions the first few times you use a new machine to help make sure you have the knowledge it takes to use it correctly.

Work safely: As mentioned, many of the new alloy wheel/tire combinations have a closer safety bead-to-rim clearance. This may require higher air pressure to seat the beads. If 60 to 80 psi is required to seat a bead, use a tire inflation cage for safety. For your personal safety and comfort, use safety goggles or a face shield, good work gloves and ear protection.

Inflate the tires to the correct pressure: Have you ever checked tire pressures and found 36 psi or higher all around? Some people inflate their tires to the inflation pressure shown on the tire sidewall. However, if they read more closely, they would see that it says “Max Press.” This is the maximum inflation pressure that the tire is built to take under normal operation. It is not the inflation pressure that should be used for day-to-day driving. The factory-recommended tire pressure is usually on a sticker in the glovebox door or on the vehicle’s driver’s door B-pillar near the door latch. Make sure you check tire pressures when the tires are cold (room or outside temperature—the vehicle has to sit for a while) and use a decent tire gauge for accuracy.

Using the Right Equipment: Tire Changer Technology

For most late-model alloy rim/tire service requirements, conventional tire changers may be obsolete. The center post tire changer was designed primarily for servicing steel rims.

“So we have larger wheels, lighter materials and lower aspect ratio tires. Why can’t I use ‘old faithful,’ our center-post tire machine?”

For starters, the bead breaker on this type of tire changer was never intended for low profile tires and today’s “rim protection” tire designs. Many low profile tires are designed so that the sidewalls stick out from the flange on the rim. This helps protect the rims from curb damage. So using the shovel-type bead breaker on this type of tire can cause tire and/or rim damage. The tire may leak, the bead may fail later on, or the shovel may slip off the high protection portion of the tire and slam into and gouge the rim. If the shovel is placed closer to the tread area, it can cause the tire to be severely deformed at the sidewall area. This can create an out-of-round condition, resulting in tire vibrations.

Here is something else to consider. Greater stress is placed at the center of the wheel when you are breaking the bead. So if you use “old faithful” on modern wheels, the wheels could bend during the bead breaking process. Often the older style tire changing equipment is not up to the task, as they just don’t have enough “oomph” when it comes to servicing the new tougher-to-handle wheel and tire combinations with tighter safety beads and closer bead-to-rim clearances.

Another version of a tire changer is the steel jaw table-top tire changer.

However, even this type of tire changer is not really up to the task. There are two styles of this machine. The steel jaws either clamp internally or externally against the wheel rim. In order to clamp the wheel internally, the steel jaws often dig into the rim, leaving visible marks. This can damage the anti-corrosion coatings. When this happens, it can void the wheel warranty. If you use a steel jaw tire changer with external clamps, the wheel rim flange can be damaged because of slipping. Most machines of this type are air-driven. During busy shop periods, air pressure can drop below acceptable levels, which may mean less clamping pressure. Eventually, this slippage will cause the clamping jaw points to wear, which will prevent them from gripping effectively. So there is a good chance the rim will not remain secure and will be scored (damaged) as it spins around.

Okay, you are convinced not to use old tire equipment on modern tire/wheel combinations. So what options do you have?

The tulip-rim tire changers are the kind! They are designed to handle today’s low profile tires and alloy wheels.

This changer has a bead roller assembly that uses a pair of rollers to push the bead loose. It applies force only to the tire and not to the wheel rim.

When removing the tire, these machines also use a clamping system that holds the wheel from the inside or outside of the rim, depending on the wheel. This type of machine can also handle centerless wheels. To keep customers happy and coming back, cushioned jaws are recommended to minimize the risk of scratching the finish on alloy wheels.

Putting the tire back on the rim is easier with the tulip-rim tire changers. The tower-mounted tool rolls the tire onto the rim as the table rotates. Even so, you will need to be careful not to position the mount/dismount head too far from the rim. Also use plastic mount/dismount heads to help reduce the possibility of damaging the tire bead. Once the tire is in place, use the high pressure air jets (if equipped) to help you get the tire bead seated quickly.

NOTE: Even when using the right equipment, it is important on large, low profile tires to always use plenty of good quality paste type lubricant (no soapy water) on the bead, the wheel drop center and bead seat. This will help prevent possible tire damage and make tire removal/replacement easier.

So what is our recommendation regarding tire equipment? After careful evaluation of leading manufacturers tire machines, we recommend using Hunter’s Auto34 Tire Changer. This built-tough tire changer has features that work well together for our wheel and tire combinations. This is important when it comes to performing tire changes more safely and efficiently. It also keeps your customers happy and the warranty clerk from coming down on you. You may need to do some match-mounting of tires for those special hard-to-balance tire situations. The Auto34 leverless tire changer includes automated functions that make this match-mounting process very easy with bead roller discs that allow the operator to spin the tire around the wheel regardless of aspect ratio or tire stiffness.

Tire Pressure Monitoring System

Another system that cannot be ignored is the Tire Pressure Monitoring System (TPMS). The sensors can be damaged if you are not careful when removing and installing the tire. If they are damaged, new sensors must be installed. There are many different sensors, so getting the correct sensor is essential. When removing or replacing a tire, the TPM sensors must be registered each time the wheels are rotated, swapped or replaced so that the sensors operate correctly and send the correct tire pressure from the new wheel location. If tires are rotated or service is required on a vehicle’s Tire Pressure Monitor System/Low Tire Pressure Warning System, the Signal Tech II J-50190, the Tire Pressure Sensor Activation Tool J-45295 or the Transmitter Activation Tool (J-45295-A) can be used.

Hunter Auto34 Product Features:

Leverless Tool Head - The ultra-thin floating tool head inserts itself between the tire and the wheel. It pulls up and positions the bead without levers and prevents damage to the tire and rim.

Push-Button Controls - The Auto34 features simple, three-button control for most operations.

Diameter Control - Operates all diameter functions from a single point while retaining the diameter until it is reset to allow all four tires to be serviced after setting it only once.

Wheel Support Plate - The wheel support plate center clamps for maximum diameter flexibility. It handles a wide range of wheels and provides extra gripping force and three adjustable work heights.

Quick Clamp with Cam Plate - The patented cam design safely secures the wheel through the hub and speeds the clamping process.

Electric Motor - Exerts over 850 foot-pounds of torque and utilizes continuously variable speed.

Mount/Demount Rollers - The rollers automatically indent to follow the rim profile, which gently rolls the bead from the rim with no rim contact.

Bead Press Arm - The standard bead press arm helps to mount difficult tires by holding sidewalls into the drop-center position.

Blast Inflator - The handheld nozzle allows the technician to direct bursts of compressed air where they are needed to help easily seat the bead.

Optional Wheel Lift System

The optional wheel lift makes servicing large, heavy SUV, light-truck and custom wheels easier while requiring less effort. The optional pneumatic wheel lift helps lift wheels to prevent potential injuries and fatigue from lifting heavy wheels into place.

The pedal-controlled wheel lift quickly raises the wheel, leaving the technician’s hands free to control the wheel and position it on the tire changer clamping system.

There is money to be made selling and installing tires. It may as well be your dealership and you making the money. But the right equipment and know-how are a must. Remember, no matter how you approach tire changing, it is extremely important that you use the proper tools and safety equipment. This is a must for helping to prevent personal injuries and costly damage and to finish the job right the first time.

No matter what machine you choose (or have to use) proper training is a MUST!