Vibrations may be caused by multiple sources, such as wheels over a rough road, steering or suspension issues. When a rotating component is not balanced, the imbalance causes additional centrifugal force to develop, possibly causing an abnormal vibration.

Does the customer feel the vibration in the steering wheel or the seat? If possible, drive the vehicle with the customer on a test drive, and try to duplicate the operating conditions that create the vibration or noise.

If you are trying to diagnose a vibrating component on a vehicle, the vibration (low frequency) is most commonly caused by wheels or tires. Steering wheel shimmy (sideto-side movement of the steering wheel) is always caused by tire/wheel imbalance. Low power steering rack friction can also amplify the steering shimmy response to imbalance. Normally the vehicle will show very low steering effort when compared to a known good vehicle.

Vehicle shake (up-and-down movement of the steering wheel) can occur with balanced, non-factory tires and wheels. Tire shake and shimmy will vary with changes in vehicle speed. Speed sensitive vibrations are usually due to an out-of-balance wheel. It is also possible for tire shake to occur ONLY during braking. First-order tire/wheel vibrations usually produce a vibration frequency of 10-20 Hz. In this article, we will investigate some familiar or maybe not-so-familiar incidents (vibration conditions) and their possible causes.

Always check wheels and tires first. Before you branch out into other incident checks, you should make sure it is not caused by more common wheel and tire vibration. Check, diagnose and eliminate any possible wheel and tire vibration causes. Once you have done that, it is time to check out some other conditions and clue in to their causes. Remember, when diagnosing a vehicle vibration (or any incident), you should always check ASIST first. There could be a Technical Service Bulletin (TSB) already covering your particular vehicle incident.

NOTE: Always use the Vehicle Vibration Customer Diagnostic Worksheet to help with documenting and communication. It is a good tool to help get you on the road to repairing a customer’s vehicle right the first time.

CONDITION 1: STEERING WHEEL SHIMMY

The steering wheel has a slight shimmy (side-to-side) motion when driving down the road. Some combinations of road surface and tire tread pattern can cause the tire tread to squirm slightly, and steering wheel shimmy can be the result. If you have already checked for the tire/wheel run-out, balance and excessive Radial Force Variation (RFV), you may need to check the steering rack’s sliding friction. If the sliding friction is out of specification, the rack will need to be replaced.

CONDITION 2: VIBRATION OR CHATTER DURING TIGHT TURNS

A vibration or chatter occurs when making tight turns on asphalt or c oncrete road surfaces. It may get worse as the drivetrain warms up. It can be best duplicat ed by driving in a figure eight.

Bad CVs, Sticky LSDs, and Flat Wrong 4WDs

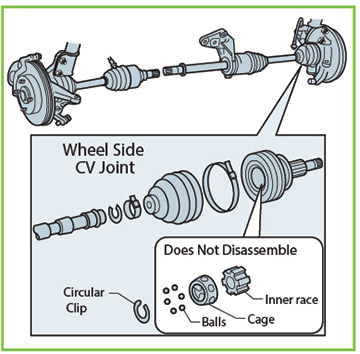

Constant Velocity (CV) Joints: CV joints are used on front-wheel drive axles. They allow the wheels to be driven and steered smoothly unlike a typical universal joint (U-joint). A U-joint tends to speed up and slow down as the angle of the joint is increased. This is because a U-joint transmits power through an “X”, pivoting on only 2 axis (directions), up-and-down and side-to-side. A CV joint powers and pivots through multiple points on the front drive axles. This smoothes out the power flow and reduces vibration. CV joints do not cause restrictions during angle changes as compared to U-joints. Sometimes inner CV joints have issues that can cause vibrations. If the CV joint binds, it can start to behave like a U-joint. What this means is that with a bad CV joint, the wheel rotation rate may speed up and slow down as the steering wheel is turned. This causes a chattering sensation to be felt in the steering wheel.

CV joint vs. U-joint: What is the difference?

The U-joint is a double-hinged joint that has two U-shaped yokes. One of the yokes is connected to the driving shaft, and the other is connected to the driven shaft. There is a cross-shaped member, called a spider, that connects the two yokes. These joints allow power to be transferred from the transmission to the final drive.

The CV joint is a refined version of the U-joint. Designed to help eliminate the variation in angular velocity, it allows movement for sharper angles, providing a tighter turning radius and making the vehicle more maneuverable.

Visually inspect the CV joints

Look for torn or damaged boots. If the boots are torn, look for contamination that may have entered the boots and verify there is sufficient grease to allow the joint to move smoothly. If the inner CV joint is damaged, the car may vibrate or knock during acceleration. If the boot is torn, the CV joint is likely contaminated and should be replaced.

NOTE: For FWD vehicles, signs of a faulty outer CV joint may be clicking noises coming from the front of the vehicle while performing sharp turns. Test drive the car safely in a full turn in both directions (in a parking lot) to check for CV joint noise.

NOTE: Do not confuse this old-school CV joint test drive diagnostic approach with modern electronic LSD functions that are part of a Vehicle Dynamic Control (VDC) system. The new system uses the ABS system and throttle control to limit wheel spin.

Limited Slip Differential (LSD)

Some Nissan and Infiniti vehicles are equipped with mechanical limited-slip differentials. If a drive wheel begins to slip in a vehicle equipped with a limited-slip differential, the difference in applied torque causes the LSD unit to apply torque evenly to both drive wheels.

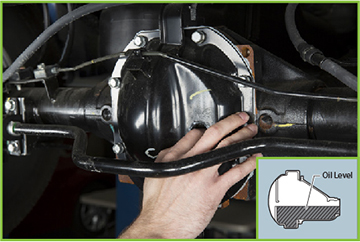

LSD oil leak

Some 4WD models use a Viscous Coupler-type LSD, built into the ring gear carrier, to provide the limited-slip function. The Viscous Coupler is filled and sealed at the factory with high tech silicone oil. The clutch plates inside the coupler heat the oil when one wheel slips, which causes the silicone oil to expand rapidly. This locks the clutch plates within the coupler that are connected to the other axle/wheel that has more traction.

Differential vibrations are almost always caused by lack of lubrication. In some cases, this silicone oil can leak out of the coupler. When that occurs, the coupler will no longer lock and unlock properly. This causes the clutch plates to drag and bind, which makes a chatter and vibration that occurs when making tight turns.

Correct LSD oil

Although the symptom is a little different, this same condition can occur with the conventional plate-type LSD unit if the wrong differential oil is used. The differential oil must be formulated for use in LSDs. If chatter is heard from a conventional limited-slip differential, drain and refill it with the appropriate oil, labeled “for limited-slip differential (LSD) use.” First check the appropriate Service Manual to see if the vehicle has a mechanical LSD and if so which type.

Wrong use of some 4WD systems

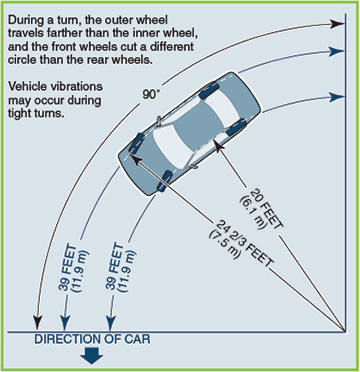

Many 4WD systems used in Nissan and Infiniti vehicles are designed to be used on dirt, gravel or paved roads in snowy conditions. When turning a corner, a vehicle’s left and right wheels will rotate at different speeds. The front and rear wheels also rotate at different speeds. On some systems when 4WD is engaged, the front and rear wheel axles are locked (without a differential) through the transfer case. When driving on loose surfaces, such as on dirt, gravel or snow, the wheels will slip slightly to allow for any difference in front-torear axle speed.

However, if 4WD is locked when driving on a dry, paved road, the wheels will grip and cause the front and rear axles to bind up. This can feel like a vibration. Advise the customer that locking his or her 4WD system should only be done during poor traction driving conditions.

CONDITION 3: HIGH FREQUENCY VIBRATION (REAR-WHEEL DRIVE VEHICLES ONLY)

At speeds above 45 MPH, there is a high frequency (fast) vibration in the seat, gearshift lever or the body panels. You may hear a droning sound as well. This type of vibration is most noticeable when driving on smooth, straight roadways that have a slight incline. On vehicles with non-independent rear suspensions like the Nissan Frontier (rigid or live drive axle), the vibration may change depending on how much of a load is being carried in the back.

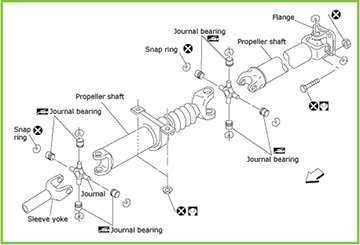

Driveshaft: What is the buzz?

On rear-wheel drive vehicles, driveshafts (sometimes called propeller shafts) can cause vibration due to improper balance, poor companion flange alignment or excessive driveline angle. Since the driveshaft turns three or more times faster than a vehicle’s wheels, typical driveshaft vibration is always faster (at higher frequency) than wheel and tire vibration.

NOTE: A U-joint running at an angle of more than a few degrees may induce a cyclic vibration in the shaft.

It is pretty easy to isolate driveshaft vibration from other sources by performing the following steps:

Check for wheel/tire vibration

1. Road test the vehicle and note the road speed when the vibration occurs.

2. Safely raise the rear wheels off the ground by placing jack stands under the rear suspension. Make sure the lift point you pick can firmly support the full vehicle weight.

NOTE: For this test to work on a vehicle with a rigid rear drive axle (like the Frontier), the rear suspension must be loaded with the weight on the suspension. The driveshaft angle relative to the transmission/rear axle must be the same as if the truck tires were on the ground.

3. Remove the rear wheels. Place all the lug nuts back onto the wheel studs and tighten them to hold the brake rotor or drum in position.

4. Start the engine. Now, with the transmission in an appropriate forward gear, increase the vehicle speed until the speedometer indicates the road speed where you felt the vibration during your road test.

If the vibration does not happen with the wheels removed, stop right here. The shaft is OK, and vibration is likely to be wheel/tire related.

Check the driveshaft for vibration

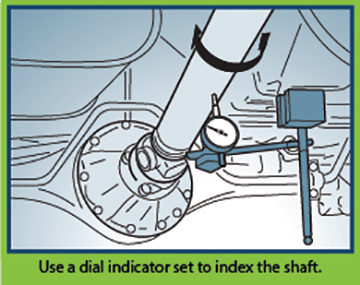

If you can still feel the vibration, shut the vehicle off and inspect the driveshaft. Are there any dents, dings or other physical damage that could put it out-of-balance? Does it look like the driveshaft has been removed? If YES, hopefully it was indexed and bolted back in the same position to the companion flange at the final drive. A driveshaft must run true to center, and it cannot have any wobble. Typically, companion flanges are relatively true to center. If the driveshaft flange and the pinion companion flange are both not exactly true, that is usually OK. But, if they were bolted together in such a way as to exaggerate this, you can get a vibration. Try re-indexing the shaft to the pinion companion flange by rotating either the shaft or the flange 180 degrees from the other. Then test it again while still supported by the jack stands.

Driveshaft angle is important

Also on vehicles with a rigid rear drive axle, excessive driveline angle can cause vibration. Check the vehicle ride height in the rear. If it is not as specified in the appropriate Service Manual, returning it to stock may be the only way to fix the shake. You can use a Driveshaft Inclinometer tool available from TECHMATE to measure driveline angles to avoid problems associated with incorrect driveshaft and U-joint working angles.

Driveline angle generates a second order phenomenon due to the U-joint design, so the frequency is two times that of an imbalanced propeller shaft. Because of this, it will match to suspension resonances at 1/2 the speed of propeller shaft balance vibration. If the speed of your vibration occurs at less than 30 MPH and changes between accelerating and coasting, it is driveline angle. If it occurs at 50 MPH or more with no change between accelerating and coasting, it is most likely propeller shaft balance/matching.

CONDITION 4: WIND DIRECTION AND SPEED VIBRATIONS

The vehicle exhibits a vibration that is changed by wind direction and speed. Some aftermarket accessories have been known to cause vibration. This is because some of these accessories change the way air flows around the vehicle. We all know how unstable air flow feels in an airplane. Well, the modern vehicle has gotten pretty aerodynamic over the years. Now, some potential sources for this may look obvious, like that big wing stuck on the trunk lid. Some, however, are not. Some examples of accessories that can disrupt air flow and cause turbulence are bug deflectors, oversized mirrors, pickup caps (shells) or tonneau covers.

In most cases, temporary removal of the accessory and a road test can verify if it is the culprit. And in some cases, it will not be. But if a vibration is isolated to an aftermarket accessory, the customer should contact the accessory supplier or manufacturer.

Also if the car in question has loose trim or accident damage, it should be repaired first. This kind of custom bodywork can sometimes mess with more than just the car’s appearance.

NOTE: The brake pedal may vibrate and a system operation sound may be heard during sudden acceleration and cornering when the VDC, TCS, Brake assist or Brake force distribution, or hill start assist is operated. This is not a malfunction.

CONDITION 5: STEERING WHEEL SHIMMY WHEN BRAKING

Does the customer feel a vibration in the brake pedal under moderate to hard braking?

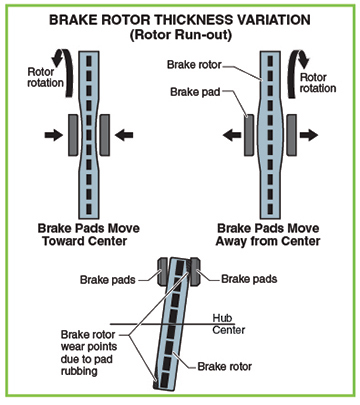

The vehicle exhibits steering wheel shimmy or brake pedal vibration only when braking. Brake rotors that have unevenly worn thin in spots may contribute to this. This can be an un-true (or out-of-true) rotor, meaning the rotor-braking or pad surface is not true relative to the centerline of the spindle. When the brakes are applied to an out-of-true rotor, the pads move in and out along the surface of the rotor. This motion is felt as a shimmy at the steering wheel.

This condition can be corrected in some cases by machining the rotors. This will ensure that the rotor braking surfaces are true when compared to the wheel spindle.

Regardless of what is making the car shake and rattle while you roll if you spend the time to chase down those bad vibrations, you will be a long way down the road to having your customer singing a happy tune.